The Thing

This is my interpretation of the Addams Family's The Thing. It is a five finger walker that can also make gestures.

The intension of this robot is to live in the window of our local skateboard shop and show a wrist watch.

The robot presents the watch. In it's own unique way.

There is a lot of open questions about mechanics, materials, locomotion and the kinematics in general. Step by step each question gets answered. From me - and the collective wisdom of LMR.

The Making

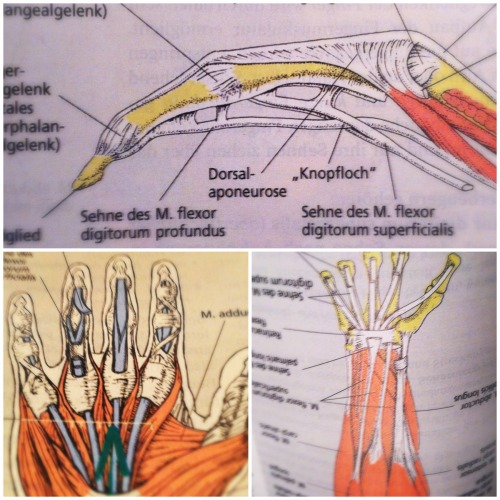

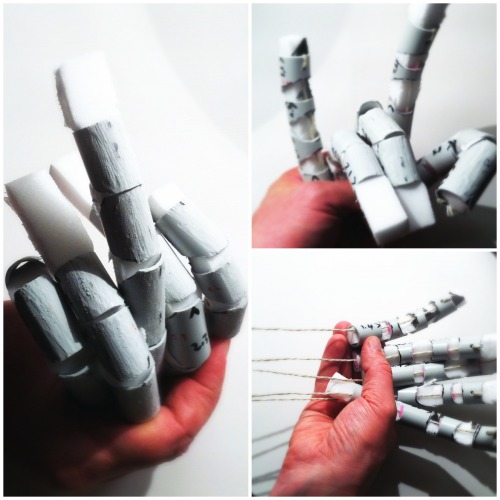

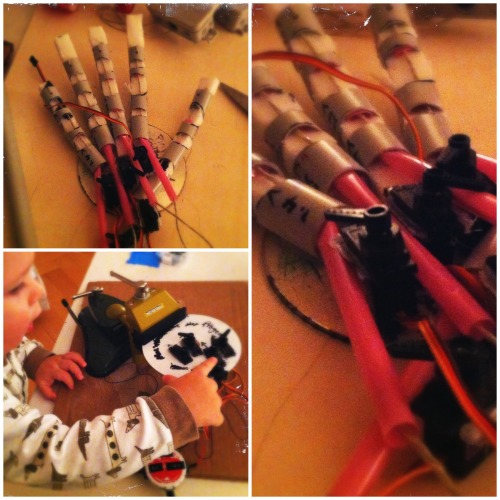

After reading a lot about human hand anatomy and DIY robot hands I started using simple materials to prototype the mechanics.

There are some inspiring ideas inside our hands. Simplified this ideas can be applied to The Thing.

Some simple straws became fingers for the first prototype. Then some water tube with a rubberband for tension.

Next prototype was made out of a pipe from the elecrician and rubber band. This design

and the pipe variant seemed adequate enough to elaborate more on the mechanics.

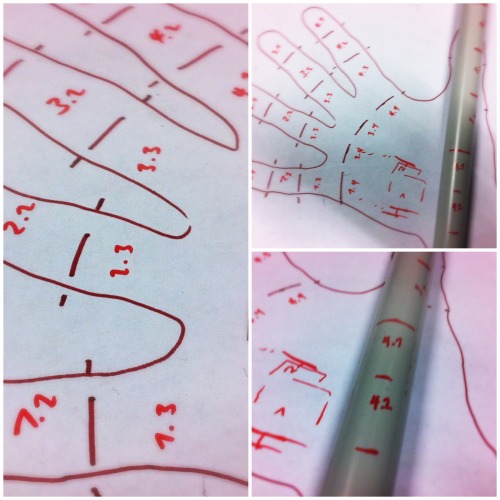

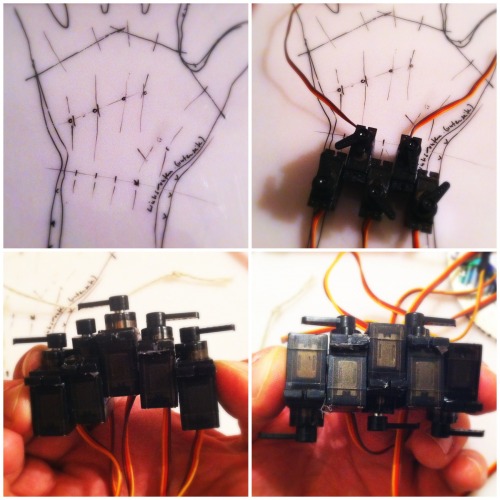

To elaborate more my own left hand became the model to find the dimensions and shape of the bones.

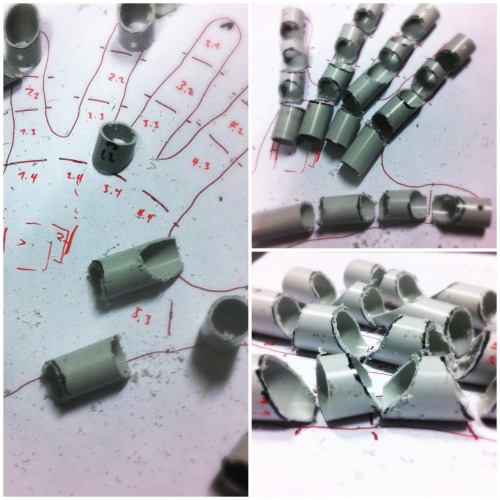

Each bone got cut from a long plastic pipe...

...and shaped according my fingers.

After an hour of cutting all parts where there.

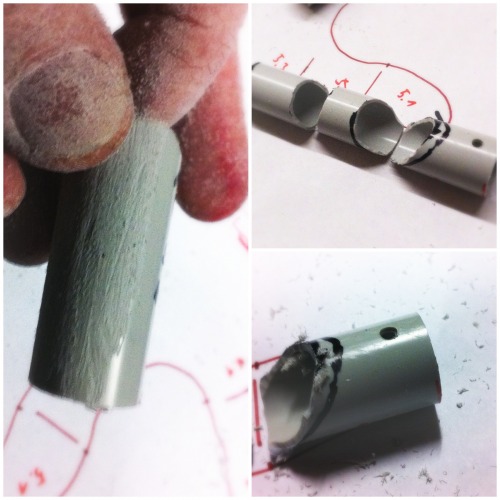

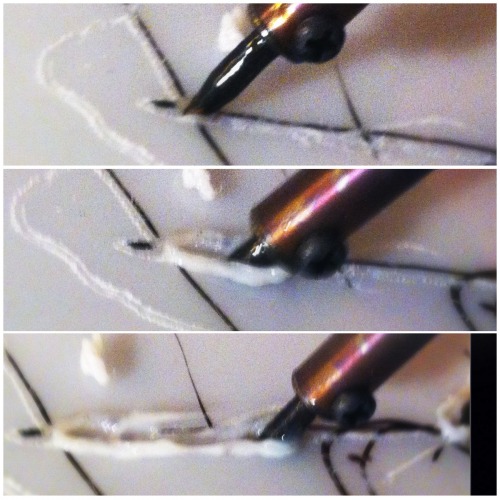

Then I drilled a hole into each fingers tip. To make shure the hot-glue sticks to the bone the bone got grinded a bit raw.

My luck two comments came in at the right time. MarkusB suggested a technique that is very interesting and in my focus now. Gareth suggested an other idea and made me consious about the finger-to-hand-fixation problem.

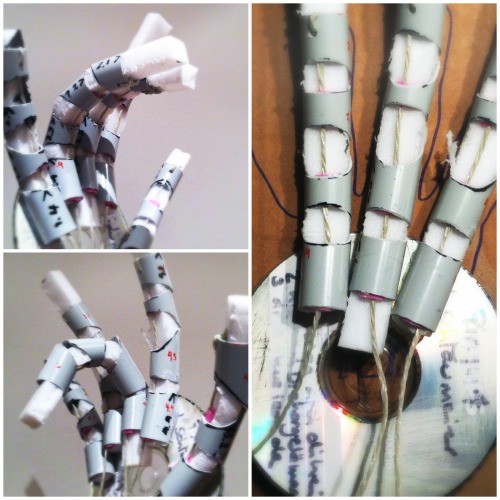

Some plastic foam material with acceptable tension is centered now inside the finger and makes the finger-move-back-straight motion look very human.

There - five fingers. First gestures.

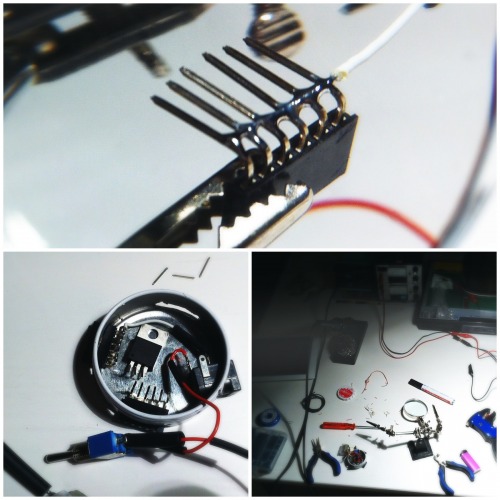

A CD was used as a base to glue the fingers on.

The fingers are in position.

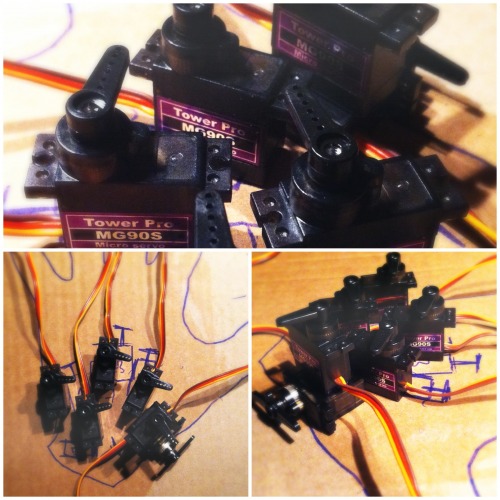

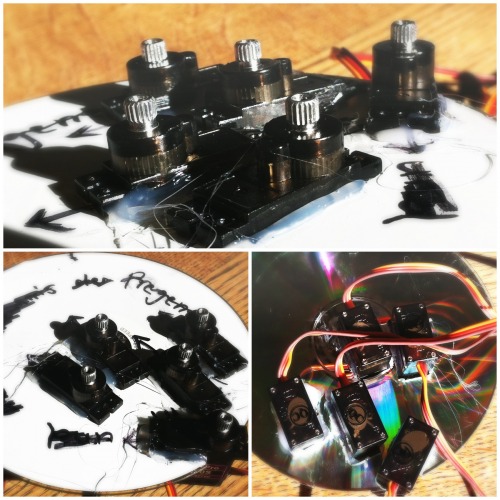

Now the servo positions had to be found.

Thought that is clever to make a plate to fix the servos to. But later it turned out, that it is

better to embed the servos there where ther is place.

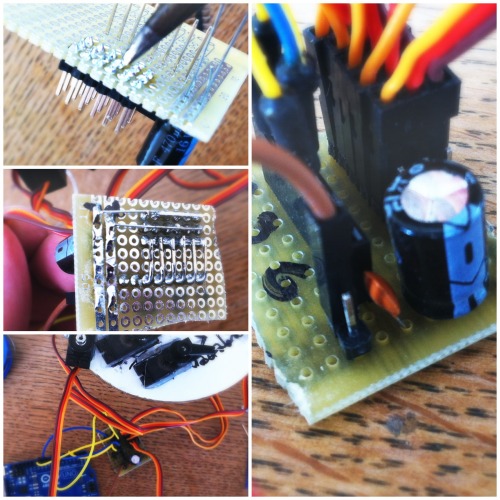

Then I soldered a servo breakout board to connect all the servos to the power. And

the PWM that gets connected to the microcontroller.

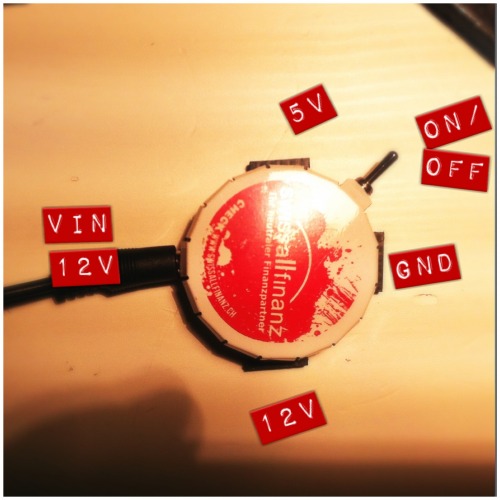

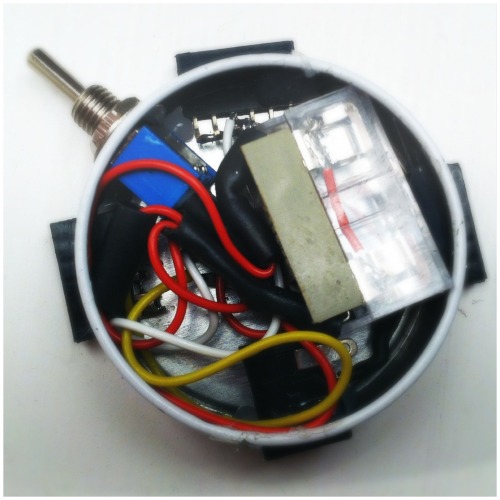

To provide power there came the idea to embed the VIN with the voltage regulator and several GNDs into a mint tin.

This is what I did and wrote this Something Else for it: Voltage Regulator in a Mint Tin.

Break.

Meanwhile I got a little distracted and went on to create a Tesla Coil to supply electricity

through air, gave a course for kids in robotics, studied the anatomy of the hand again, soldered

an analog line follower, got my Rasperry Pi, made a prototype of a small belt-conveyor,

held a lesson in software-engineering at this University of Applyed Science and built

a curved obstacle in the skatepark.

After this break the servo breakout board and the servos got tested. All fine.

Then the hand got extended with cable shafts to safely define the line where the

cables go through.

Where to place the servos is a question that followed me all the time. This mechanical

detail gave me a hard time. Not that it isn't obvious where to place them. The

human anatomy shows where they would be fitted: Close to the elbow in the

lower arm. This arm length is what I did not want. The Thing should be rather short.

So the arm should be as short as possible - only as long as needed and that it

looks good. So several servo position variants were elaborated.

Late in the night I started the dremel and grinded out the shape of a hand. But it was

so loud I had to stop and instead of grinding I started to melt out the hand shape.

The material I use here is Polystrol.

Further Readings

Simple Animatronic Hand

This hand is made from readily available materials. It serves as a good starting point for further work that might include the use of servos, remote controlling and more advanced animatronics.

A Gentler Robotic Touch

Simple and versatile robotic hands can grip a football or pick up your keys.

6 DOF Robot Hand

The primarily function of the hand is to display hand gestures. The thumb has two degrees of freedom.

Voltage Regulator in a Mint Tin

Here is a voltage divider that is hacked into a Mint Tin. In goes 12V, out comes 12V and 5V.

(Lense: Loftus)

Walk Around and Make Gestures

- Control method: autonomous

- CPU: Arduino

- Operating system: Arduino

- Programming language: C

- Target environment: indoor