Robotic Arm (AIM System)

My Learn-As-You-Go project...

A few specs for the finished project:

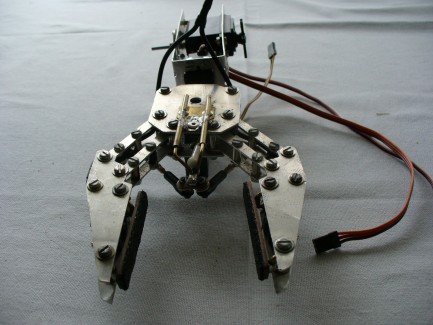

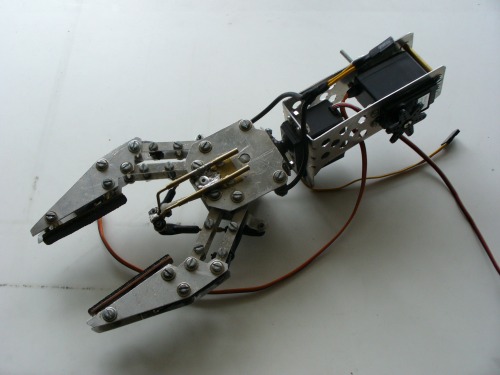

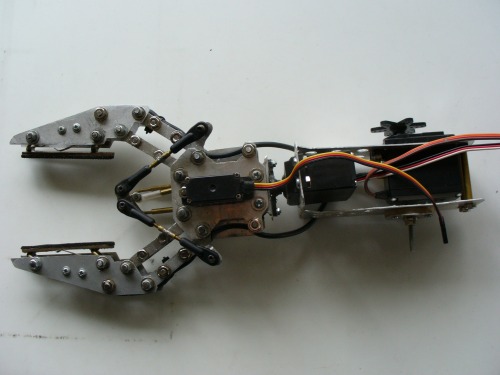

- 6 degrees of freedom - base rotate, shoulder, elbow, wrist, wrist rotate, gripper.

- 12V SLA Battery power supply

- Controlled by PICAXE 28X1

- Sensors - Microswitches in each gripper, ultrasonic unit underslung on the gripper, possibly more.

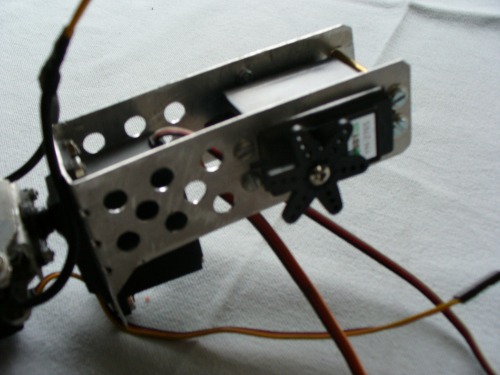

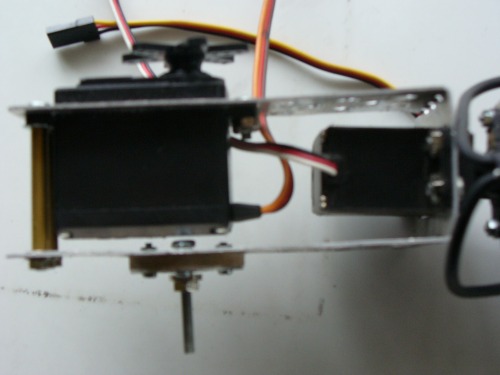

- Output devices - 8 servos (2 each for the shoulder and elbow joints), LCD and possibly a buzzer for debug.

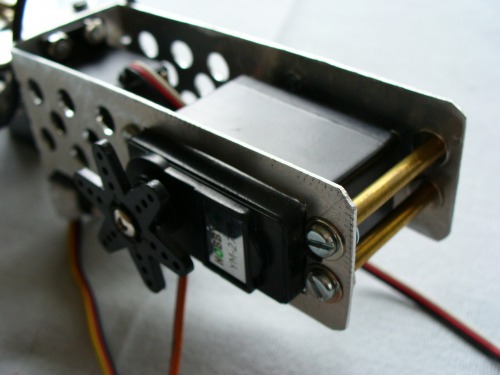

- Mainly aluminium construction, some brass and MDF parts where required

- ALL HAND BUILT PARTS. I don't buy modules, or kits, because there's nothing they can teach me the net can't.

- No existing plans. This is almost entirely my own design drawing influence from the lynx series of kits.

UPDATE 28/6/09 - Wrist Completed (Lower Arm still to be added)

Sorry for some blurry images... Camera focus really wasn't working.

Basic Robotic Arm - Able to manipulate a variety of objects within large size and location parameters.

- Actuators / output devices: Servos (8), 16x2 LCD, small buzzer, various lights for the hell of it.

- CPU: Picaxe 28x1, LCD interface Picaxe 20M

- Power source: 12V SLA Battery

- Programming language: Picaxe basic

- Sensors / input devices: ultrasound, gripper touch switches

- Target environment: Proof of Concept (Lab/Garage)