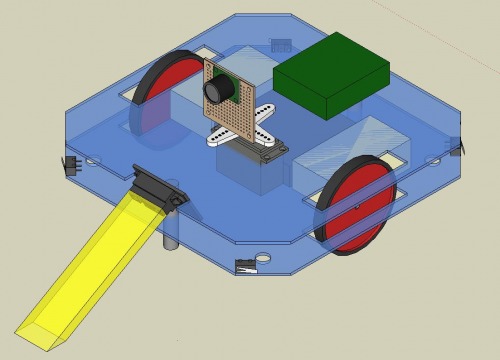

Robot 2, this time /w planning

Now that i can do SketchUp this allows me to plan my next robot a little better. I am recycling parts from my first robot Kaboodle https://www.robotshop.com/letsmakerobots/node/1284

Same plan with better execution, also a larger steadier base that is parallel to the surface. the body will be made from acrylic sheet and cut with a plastic cutting knife + and rotarty tool.

New additions i will be trying include:

-use of microswitches for bumpers

-RF link for remote conection

-cliff detection with IR

-IR beacon for docking

After staring at the model for a bit i might go with 2 casters instead of 1 and move the wheels closer to the center for more stability, the new caster will be at the rear.I wil aslo move the servo back as to even out the weight distribution, and make it so that the sonar is closer to the center.

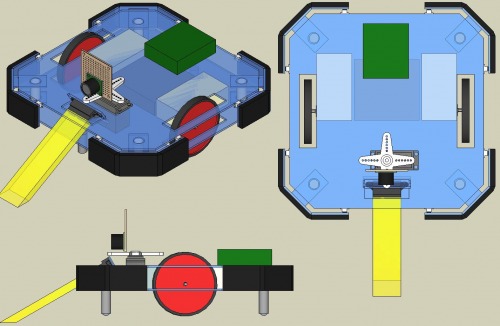

Design #2

Addition of bumpers. I will not use microswitches, but 8x reset button switches for this. (little white things in the image)

The contact points at the bottom will be home made ball casters using: brass tubing, a bearing, and a spring

Update, Sunday Aug 03

Time to build!

This is the base using plexiglass with cutouts for the wheels and nylon standoffs to support the next tier of plexiglass.

plexiglass is a tough process to cut with a rotary tool, next time ill have it lazer cut instead...

I originaly made a bearing caster with brass tubing. But it was too tall. If i made it any shorter, the components inside would no longer fit. I would need a smaller tube, bearing, spring and nut altogether. so i decided to try out metal screws as casters in the meantime. I hope they'll perfrom well, its nice because you can adjust their heights too.

http://www.solarbotics.net/starting/200209_ballcasters/200209_ballcasters.html

object avoidance, auto or remote, expandability for peripherals

- Actuators / output devices: 1xServo, 2xGM3 motors

- Control method: Rf link or autonomous

- CPU: Picaxe 28x1

- Power source: 4xAA batteries

- Programming language: Basic

- Sensors / input devices: 1xsonar 1xIR 4xmicroswithces

- Target environment: indoor, hard floor