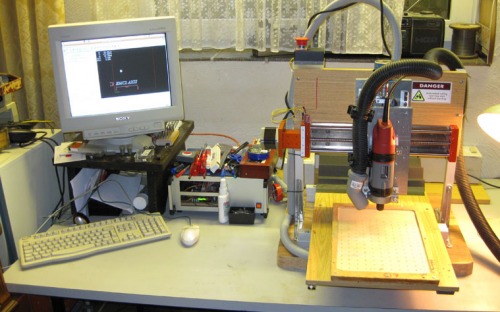

My selfbuild CNC-Mill

For now its almost done! My selfbulid CNC-Mill is ready to use.

It all started during my x-mas holidays when I found Tinheads Valkyrie here on LMR. I had the idea of bilding a CNC-Mill before, but the whole thing seemed to be to complicated. But then, inspired by Tinhead I started reading DIY CNC-pages for hours and hours and after a few days I started building it. My first machine had a lot of mistakes (you can see the history here: https://www.robotshop.com/letsmakerobots/node/16392), but i learned a lot by doing so.

So here are some facts about the final version:

Working Area: 310x310x10mm

Working speed X&Y up to 5000mm/min, Z up to 500 mm/min

The movement of the axis is controlled by stepper-motors with 200steps and 4A phasecurrent.

The PCB for the stepperdriver is bought here: www.mechapro.de (3D-Step)

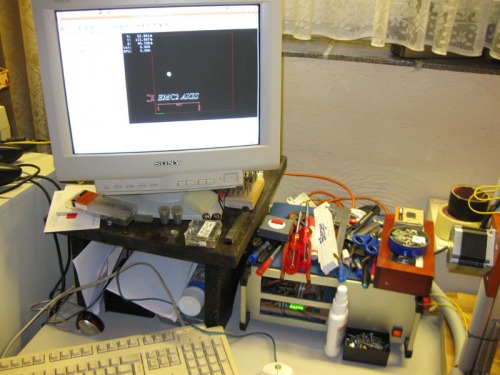

The whole system is running under ubuntu-linux und EMC2 (linuxcnc.org) on an old PC (Athlon XP 1,6GHz - 512 MB Ram - 8GB CF-Card as harddisk)

What did it all cost:

- woodparts: 0€ (every woodpart is "recycled")

- aluminium: about 70€

- linearrails: 100€ (ebay)

- the whole Y-axis: 35€ on ebay (this was really really cheap!!!!)

- linearscrew 16x4 for the x-axis: 25€ (ebay - 1 I had already before)

- Stepper-motors: 16€ (ebay)

- ballbearings: about 15€

- Stepperdriver-PCB: 20€

- Stepperdriver-parts: about 30€

- Stepperdriver enclosure: 0€ (it's an about 20 years old dual 5-1/4" floppy-drive enclosure)

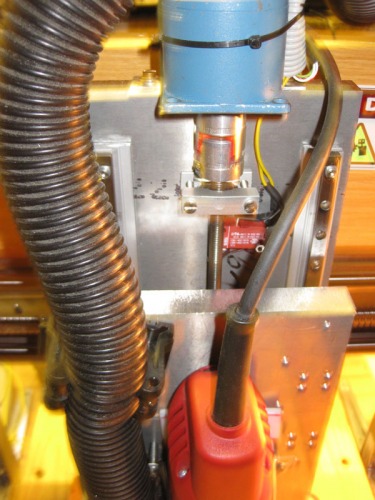

- Spindle (Kress FME 800): 120€

- 24V Power-Supply: 8€ (ebay)

- 5V Logic-Supply: 0€ (old small ATX supply)

- PC: 0€ (put together the best old parts i had flying around)

- misc. electronic parts (relais, darlington, cable, etc.): about 20€

all together (including things i have forgotten) about 500€

If someone has a question - feel free to post here, I will answer as fast as possible!

a few more pics:

Things to get changed someone in the (deep) future:

- Working-tabe made of 20mm Aluminium (80€) an a T-Nuten table (don't know the english word)

- a frame made of steel or aluminium (no more wood)

- better mount for the spindel

- depth-regulation for better engraving/pcb cutting

- 4A/phase update for the stepperdriver

- better interface for manual control (broke already a few bits through pressing the wrong key.....)

- better vacuum system for dust removal....

Update 1.10.2010:

New Video: Now its possible to play music on my cnc ;-)

made with mid2cnc

CNC Stuff....hopefully...

- CPU: Athlon XP 1, 6GHz

- Operating system: Linux (Ubuntu)

- Sensors / input devices: End-switches

- Target environment: indoor