Maxwell, A Mobile Manipulator

Maxwell is my latest attempt at a lowcost, human-scale mobile manipulator using an ArbotiX and ROS. The design guidelines were pretty straight forward: it needed an arm that could manipulate things on a table top, a Kinect for primary sensor on the head, and a mobile base that kept all that stuff upright. Additionally, I wanted the robot to be easy to transport and/or ship.

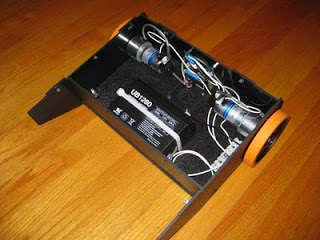

Maxwell sports a larger 16x16" version Armadillo base with motors that should support a 20lb payload at speeds up to 0.5m/s. Not shown in these images is a Hokuyo URG-04LX-UG01 which will be mounted on the base, just in front of the column. The head has two AX-12 servos for pan and tilt. Eventually, the head will include a shotgun microphone.

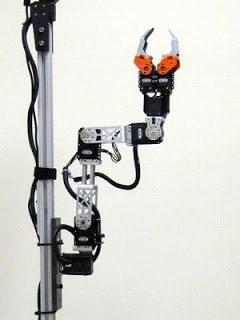

Maxwell's arm is constructed from 2 EX-106 (shoulder lift and elbow flex), 2RX-64 (shoulder pan and wrist flex), and and 3 AX-12s (one for wrist roll, and two to form a gripper). In all honesty, it only needs the one EX-106 in the shoulder, but I didn't have any brackets that fit the RX-64 at the moment. The actual gripper fingers are temporary, I have much better ones in the works.

His central column consists of 3 sections of 8020 aluminum support, allowing all pieces to break into lengths under 20" long. This allows Maxwell to be disassembled and put into a reasonable size Pelican case for shipping. It only takes about 5 minutes to break down or setup Maxwell, as you only have to loosen 6 screws.

Maxwell will be competing in the AAAI Small Scale Manipulation Challenge later this summer. After the AAAI event, he'll probably get an upgrade for a vertical lift on the arm (similar to the one on Georgia Tech's EL-E) and possibly a conversion to two more anthropomorphic arms.

Navigation, object manipulation, other mobile manipulation research tasks.

- CPU: Dell Vostro 3400, ArbotiX2 RoboController

- Operating system: Ubuntu Linux, ROS

- Power source: 12v SLA, 8Ah

- Programming language: C++/Python, ROS

- Sensors / input devices: Kinect, Hokuyo URG-04LX-UG01