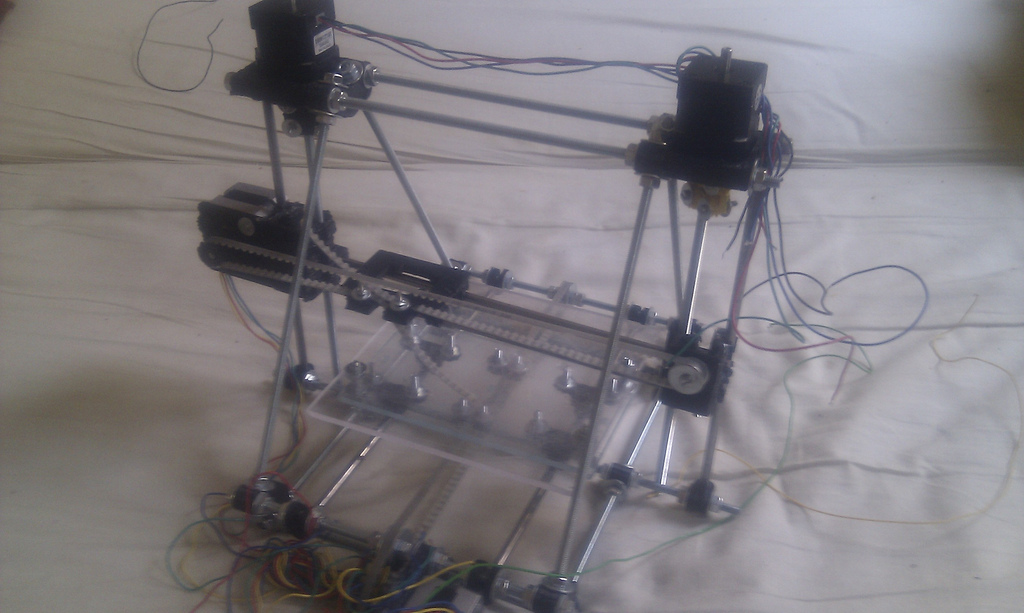

Doboz: Repstrap 3d printer made of Aluminium and plexiglass

Hello everyone ! Since this machine has just finished producing its first "offspring", i thought i would submit it here to commemorate.

This is my first generation "Repstrap" machine , on which i worked for many months.

- A repstrap is a derivative of a Reprap (open source 3d printer) , that is not created using 3d printed parts (sort of like "bootstraping" such a machine)

- as with most machines of this kind, it prints 3d object using thermoplastic filament that gets melted and extruded via the print head, depositing layer after layer

- The structure is made of L-Shaped aluminum : outer volume is 39*35*45 cm

- Total build volume ( maximum size of objects that can be printed inside of it) is 21*18*23 cms - I used a threaded rod approach for all axis of the cartesian bot (in hindsight, not the best idea, as low quality threaded rods make movement way too slow)

- Custom, low cost home made electronics to control all stepper motors , the print head heating , and the heated build platform (used to avoid warping in cooling objects)

- it also has a very limited 3d scanning ability, using a simple IR-Led/Photodiode combo , to generate 3d "height maps" of the objects in the machine .

- overall, a rather slow but rather reliable machine ( many 24/7 prints) It has already allowed me to experiment with different mechanical components, and has just finished printing its first offspring; a mini reprap!

The build process was spread out over about 8 months, with many prototypes, and experimentation, i had never worked on something this complex before, and even with the occasional tantrum etc, great experience :)

You can view more info and aspects of the build process on my site :http://www.kaosat.net/?tag=repstrap

Cheers!

http://www.kaosat.net/wordpress/wp-content/uploads/2010/09/wpid-IMAG0883.jpg

3d printing, a bit of 3d scanning

- Actuators / output devices: 5X stepper motors

- Control method: multiple at mega connected to host pc

- Power source: PC psu molex connector

- Programming language: C++, C, Python (on host)

- Target environment: indoor