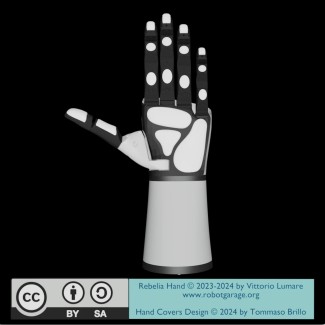

So, in 2023, I started a project to create an affordable prosthetic robotic hand, which I completed in 2024.

A friend of mine with a transradial amputation helped me with valuable feedback to make the hand the best it could be from a user’s point of view.

When I began exploring how to produce, sell, and distribute the hand to those who need it, I, unfortunately, encountered the harsh reality of medical certification: an essential process with the unintended consequence of stifling small companies' projects at the outset.

So, I decided to slightly shift the target: a hand for robots instead of humans—an easier project to start with, at least in terms of safety, regulations, and costs.

The idea is that the version for robots can be improved rapidly (with a new version each year) without the burden of re-certifying it medically (which is extremely costly and time-consuming).

This way, as a company, we aim to create a super reliable and innovative version in just a few years. If the business proves successful, we will then be able to launch our next project: the prosthetic version for humans.

Last but not least, with each new version we release, we will make the previous version open-source.

Currently, the project is in its finalization phase (final improvements, testing, EU certification, business planning, marketing), and we plan to start pre-sales soon.

But before we proceed, we need to understand exactly what the community wants: we need your impressions, wishes and advice, as robotics enthusiasts and engineers.

The design, schematics and software of each product version will be released under an open-source license once a minimum earnings threshold is reached, necessary to ensure business sustainability. A key requirement is that the company must continue to operate and not fail.

We plan to offer this affordable robotic hand to students, researchers, prototyping companies, and service robotics companies.

The price is expected to be in the range of € 1,500–2,000.

Students and researchers will finally be able to include a robotic hand in their research projects and theses, instead of merely dreaming about it.

Prototyping and service robotics companies will save significant costs by using an affordable product, rather than spending over 10,000 EUR on a super complex and expensive robotic or prosthetic hand they may not even need.

The hand is currently not suited for industrial environments, but we can develop an industrial-grade version if required.

This version would need greater durability and reliability, necessitating the use of higher-quality materials and more advanced manufacturing processes, which would increase costs.

Additionally, developing an industrial version would demand more financial and resource investment, which we currently do not have."

Once the product reaches a mature stage and the company gains more financial resources and expertise, we can begin developing the prosthetic version, conducting clinical trials, obtaining medical certification, and completing all the necessary steps to release a safe medical device.

The prosthesis would be distributed through the national health system of each country to individuals with a medical prescription, and the price must remain within the limits supported by the system. We don’t want people to pay out of pocket, as many cannot afford it, and the hand must be accessible to all."

While similar projects exist in other countries, at the moment the cost remains too high for many, including in Italy.

Our goal is to ensure the hand remains accessible to everyone, regardless of circumstances.