3-Axis CNC Vertical Milling Machine : MazeMill V0.1

So the time has finally come, I had some time this weekend and started turning plans and ideas into reality. I have been researching and studying milling machine, professional and homemade ones alike, for many months now. I think i finally have enough information to give it its first go.

Today I recieved 4 step genies and some mosfets, I also have 4 nice steppers on their way from ebay. In the recent months ive collected a variety of bits and pieces which i thought would come in useful, such as some threaded rod, first standard 3/8"-16 and then a few days ago i got my hands on some M10-1.0 threaded rod, which will probably be a bit more precise and easier to calculate with. 200step/turn stepper, gives 10/200=.05mm per step, that should be plenty of precision for any project. My goal for now is to have everything square and level so id be happy if i get 1mm precision..

Anyway, my design is a mix of things ive seen around the internetand and a few of my own ideas, I wont go into detail at this moment since i am still working them out myself.

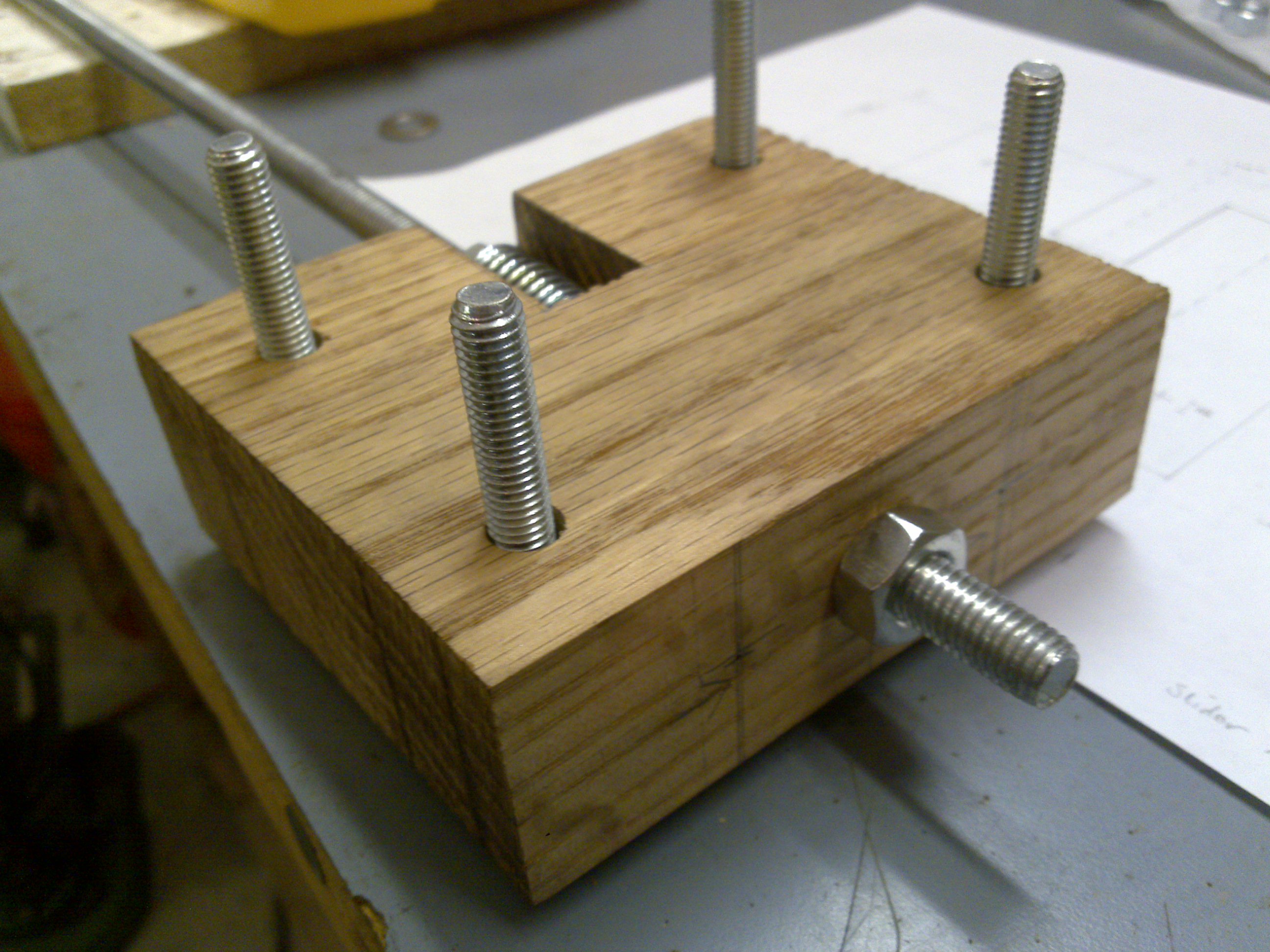

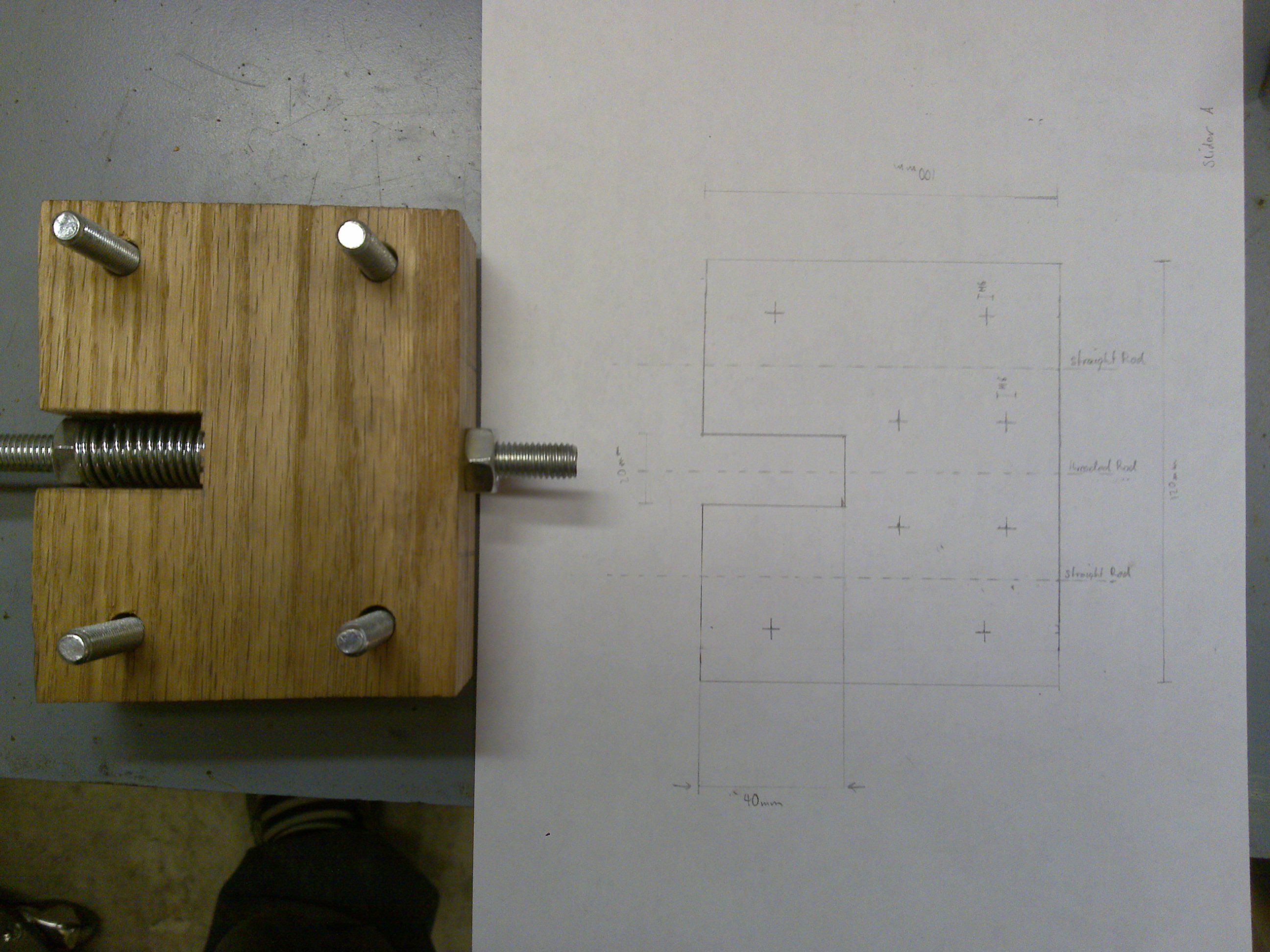

The Basic Design: Its going to be a vertical milling machine, with the x and y direction coupled into an x-y table (duh!) and the z axis mounted above the x-y table, therefore resembling a typical vertical milling machine. I will be using the anti-backlash leadscrew cradle, which Honus posted on Instructables.com(http://www.instructables.com/id/SXLO9X0FPKFCR62/). As soon as i will be scanning my current plans I will post them here, for now take a look at the Leadscrew cradle I finished today:

this is the Y cradle, a 100x120x50mm block of oak(best thing i could find) with 4 M8x1.25 bolts which will be for mounting the X cradle in the future. The bolt on the right will still needs to be fitted into the block so it wont turn when the leadscrew does.

For the Mill neck(? not sure if that the right term) I am layering 6 layers of plywood/OSB to create a solid block of wood which will need to be sturdy enough to support the milling head/drill/dremel. But before I went to glue 6 layers of ply wood together I first wanted to test for the stongest bonding glue. So I went to the hardware store and after some looking narrowed it down to Good ole' gorilla glue and gorilla wood glue.

So I cut a few small pieces of plywood and glued them together,

^^Gorilla Wood Glue, doesnt foam and doesnt need to have a dampened surface

^^Regular Gorilla Glue, dampened both surfaces, aplied glue, waited ~5min and then clamped down.. here you can see the Gorilla glue foam which occures when it starts setting.. supposedly it expands 3-4times its size during the curing process

now to the results, i let them harden for about 8 hours and then i did a hammer test ( put the piece on its side and slam down as hard as i can, I know not very scientific, but it works.

^^cross section cut left gorilla glue, right gorilla wood glue

^^Gorilla Glue: After 2 pretty hard smashes the plywood broke, so the wood and the resin with which the plywood is made broke before the glue did!

^^Wood glue: 1 hit and it split right at the glue.

Conclusion: Wood glue may be good for some things.. when you cant wet a surface or when it cant bubble out., but overall regular Gorilla Glue is much stronger. Therefore my Mill Neck will be held together by regular gorilla glue =)

well this is it for today, but I will have more tomorrow night. hopefully Ill have at least one of the leadscrew cradles and slider assemblies done.