2009 FIRST FRC Robot, Team 2197

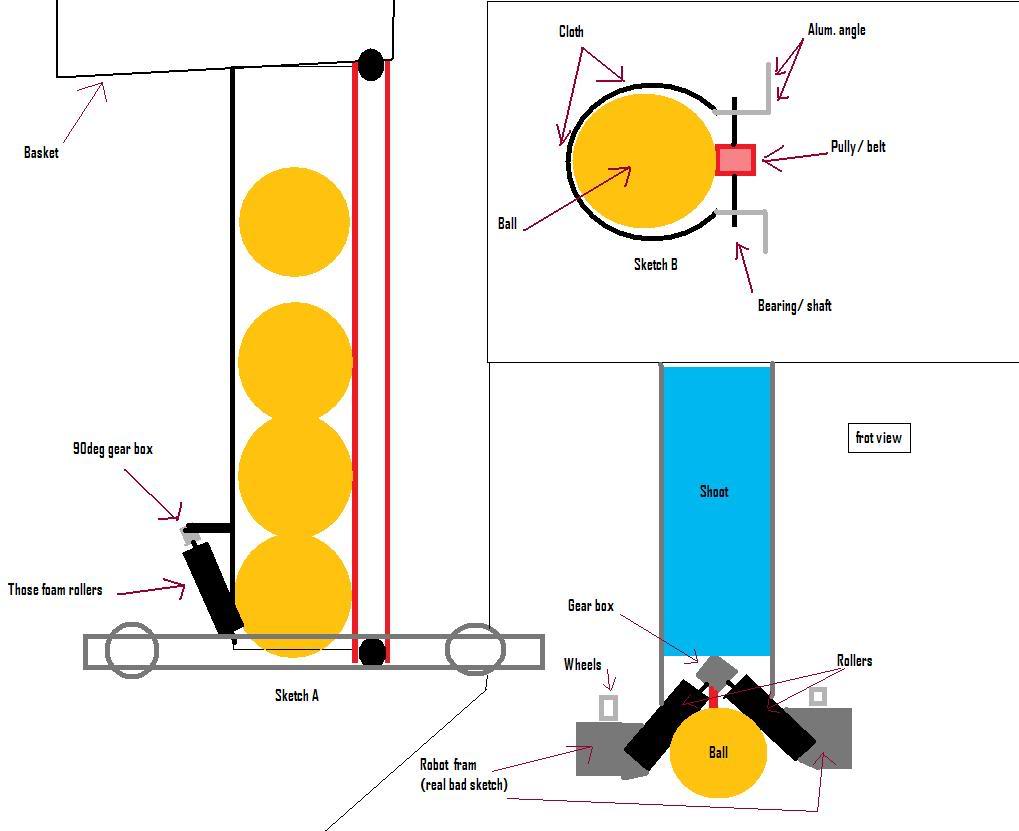

Ok this year we had to design a robot that could successfully collect these “moon rocks” and then deposit them in the trailer of the opposite alliance.

Sounds pretty simple but!!!

It has to weigh less then 120lbs, fit in a 28”x38”x60” box, use only specified motors and pneumatics (we used no pneumatics this year), use only a certain battery, and a hole list of other rules (three ring binder full). But still you have a lot of freedom to design whatever you want. Oh and we only had six weeks and a budget that is set by FIRST. It’s all to keep things equal though so it’s cool.

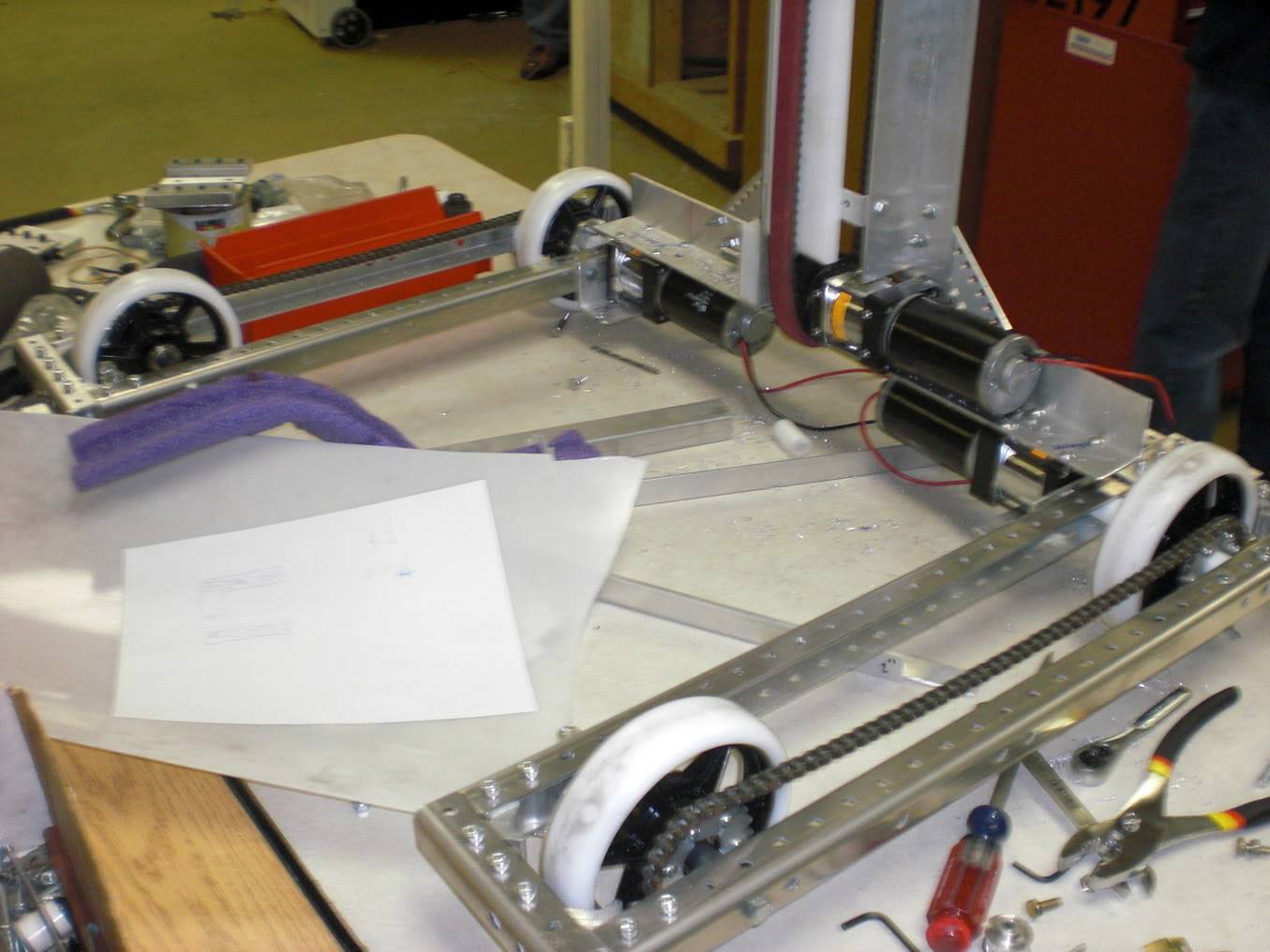

Andrew Early (remember that name) and I basically designed the thing during lunch and after school for a week straight. It got very intense at times because there are so many different ways to accomplish the task given to us. Upon finalizing the designs we started to scavenge for parts and assemble things.

About five weeks later we had it built, programmed, crated and shipped to Ohio for our first reginal where we placed 6th place out of 59 teams.

I could write an entire book on the many long nights we spent building this, and all the different ideas that came to mind in the process but to spare the life of my keyboard and your focus I will leave it at this for now. As anyone who has ever built a robot before knows, I love to be asked questions about my creation so please feel free to ask them. Like I said I know I left out a lot of details but I can’t possibly answer every question someone might have, so please just ask in a kind manner and I will be glad to answer anything for you. I had a ton of photos on fliker but apparently my account got switched or something and I lost them all, ill figure something out soon. If your dispirit to see more, again just ask and ill e-mail some to you.

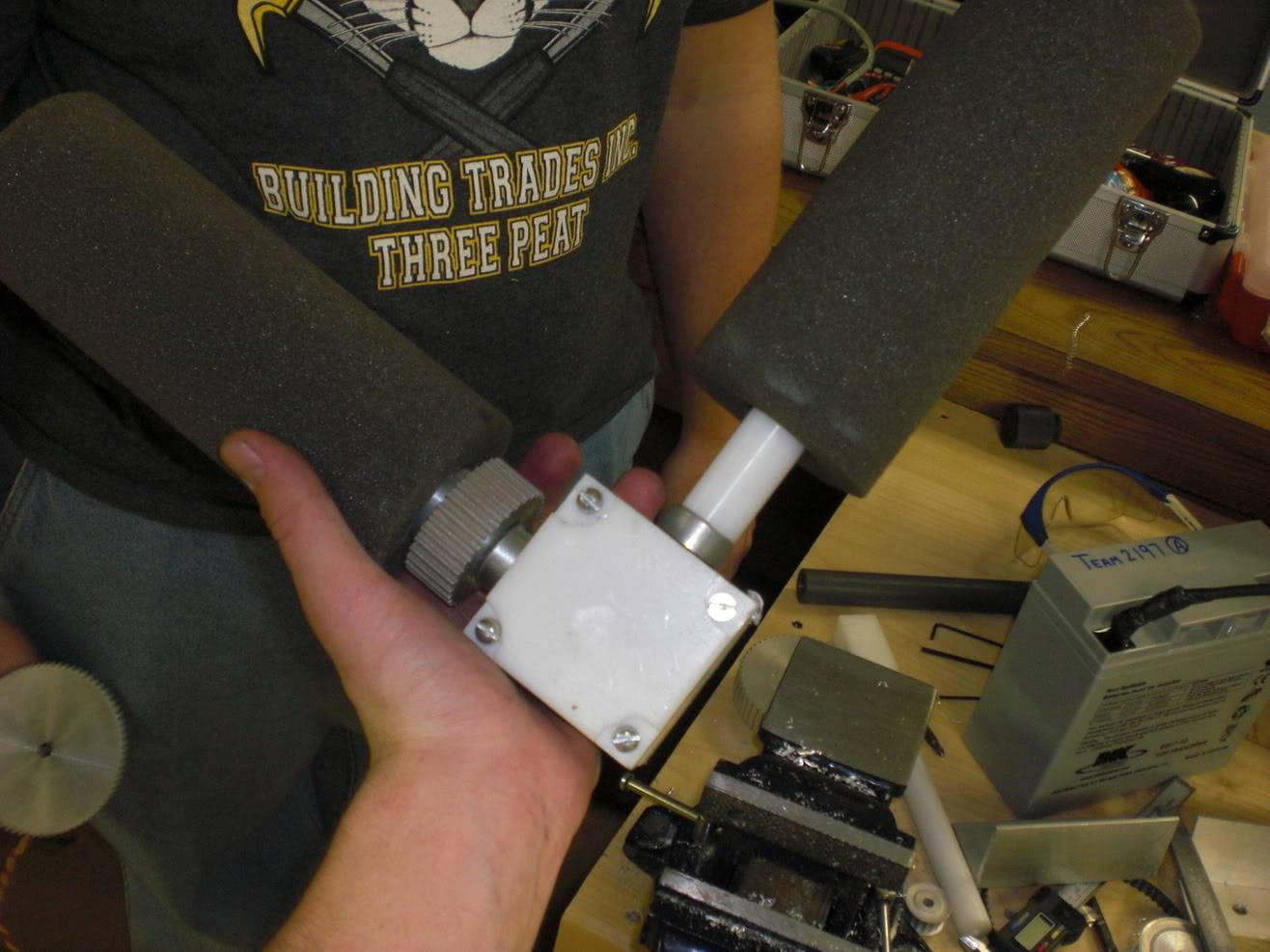

^^^^They dont even sell these anymor, so we were so lucky to have found a few!!! ^^^^

^^^^

Instead of using a bunch of pulleys and stuff I had the brilliant idea of just putting the intake rollers at a 90^deg angle and linking them with a gear bot. Only problem is we didn’t have a gearbox like that… But a company who gave us a lot of materials (E-Pak Machinery) had two bevel gears laying around and some thick plastic that machines like a god. Lo and behold this is what we ended up with. Though there isn’t that gear on the shaft anymore, it was replaced with a single motor direct drive much more eficent. I don’t know if I have a picture of that… Had so much fun making this!!!

Built this for the 2009 FIRST Robotics Competition "Lunacy"

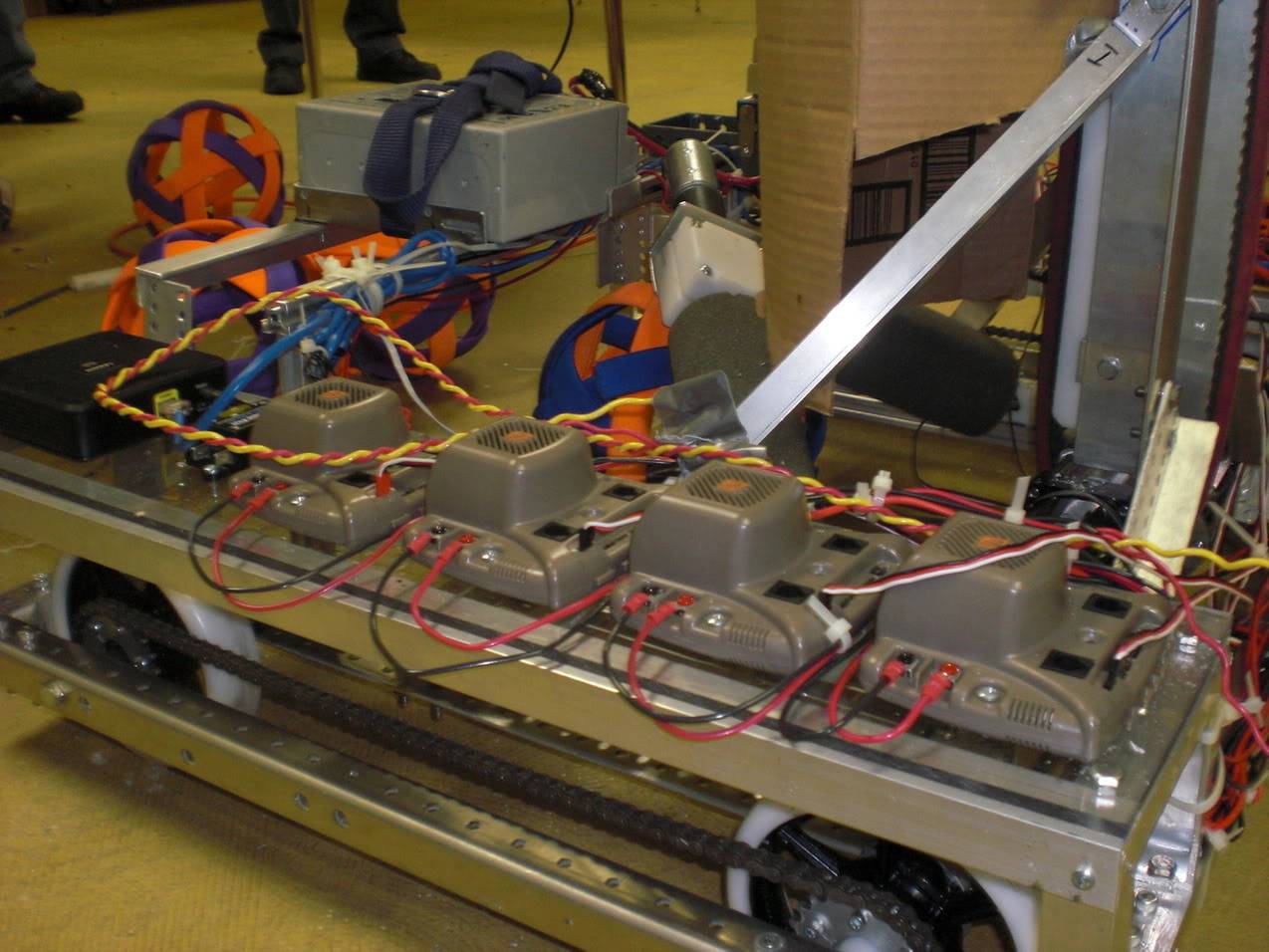

- Actuators / output devices: We used two SIMs in conjunction with planetary gear boxes for something like 1:24 direct drive. And a few other motors just ask if you want to know!

- Control method: Autonomous for the first 15 seconds of a two minute match. Communication is 802.11n, and USB joystick.

- CPU: freescale MPC5200 inside the Compact Rio, 32bit from National Instruments. I think its practically a full blown PLC.

- Power source: 12v 16 amp/ hour

- Programming language: LabVIEW

- Sensors / input devices: There is a network camera for target (trailer) tracking.

- Target environment: Played on a field with 5 other robots, the flooring was made of shower liner (the stuff commonly used in gas station bathrooms) it’s all bumpy and plastic; you know what I’m talking about.