UFACTORY Robot Arms Compared: Picking the Right One for Your Application

UFACTORY has carved out a neat niche in the cobot world, with industrial grade arms, open APIs, and pricing that is accessible for education, research labs, and small manufacturers. Their lineup centers on three main families: the Lite 6, the xArm series (5, 6, and 7), and the long reach 850, supported by a growing ecosystem of accessories and software tools that all work well together.

If you’re trying to decide which UFACTORY arm fits your project, or if you want real examples of these robots in production, this post walks through the product families, highlights where each one shines, and connects them to concrete case studies.

The Lineup at a Glance

At a high level, the three main UFACTORY robot families cover different roles:

- UFACTORY Lite 6: Compact, 6 axis desktop arm for education, research, and light, low payload automation.

- UFACTORY xArm 5, 6, 7: Flagship 700 mm reach cobots for general automation, with payloads from 3 to 5 kg.

- UFACTORY 850: Long reach (850 mm), 5 kg payload, high precision arm for tasks that need both workspace and accuracy.

|

|

|

|

|

|

|---|---|---|---|---|---|

| Model | Lite 6 | xArm 5 | xArm 6 | xArm 7 | UFACTORY 850 |

| Specification | |||||

| Payload | 0.6kg | 3kg | 5kg | 3.5kg | 5kg |

| Reach | 440 mm | 700mm | 700mm | 700mm | 850mm |

| Degrees of freedom | 6 | 5 | 6 | 7 | 6 |

| Repeatability | ±0.5 mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.02mm |

| Maximum Speed | 0.5m/s | 1m/s | 1m/s | 1m/s | 1m/s |

| Weight (robot arm only) | 7.2 kg | 11.2kg | 12.2kg | 13.7kg | 20 kg |

| Temperature Range | ─ | 0-50℃ | 0-50℃ | 0-50℃ | 0-50℃ |

| Power Consumption | ─ | Typical 200 W, Max 500 W | Typical 200 W, Max 500 W | Typical 200 W, Max 500 W | Typical 200 W, Max 500 W |

| Robot communication | Modbus TCP (Ethernet) | Modbus TCP (Ethernet) | Modbus TCP (Ethernet) | Modbus TCP (Ethernet) | Modbus TCP (Ethernet) |

| End Effector communication | Modbus RTU (RS-485) | Modbus RTU (rs485) | Modbus RTU (rs485) | Modbus RTU (rs485) | Modbus RTU (rs485) |

| End Effector I/O | 2* Digital Input 2* Digital Output 2* Analog Input 1* RS485 |

2* Digital Input 2* Digital Output 2* Analog Input 1* RS485 |

2* Digital Input 2* Digital Output 2* Analog Input 1* RS485 |

2* Digital Input 2* Digital Output 2* Analog Input 1* RS485 |

2* Digital Input 2* Digital Output 2* Analog Input 1* RS485 |

| Movement | |||||

| Maximum Speed | 180°/s | 180°/s | 180°/s | 180°/s | 180°/s |

| Joint 1 | ±360° | ±360° | ±360° | ±360° | ±360° |

| Joint 2 | ±150° | -117° ~ 116° | -117° ~ 116° | -117° ~ 116° | -132°~132° |

| Joint 3 | -3.5°~300° | -219°~10° | -219°~10° | ±360° | -242°~3.5° |

| Joint 4 | ±360° | -97°~180° | ±360° | -6°~225° | ±360° |

| Joint 5 | ±124° | ±360° | -97°~180° | ±360° | -124°~124° |

| Joint 6 | ±360° | ─ | ±360° | -97°~180° | ±360° |

| Joint 7 | ─ | ─ | ─ | ±360° | ─ |

| What's Included | |||||

| Robotic Arm | Lite 6 | xArm 5 | xArm 6 | xArm 7 | UFACTORY 850 |

| Control Box | Built-In | ✓ | ✓ | ✓ | ✓ |

| Control box power cable | ─ | ✓ | ✓ | ✓ | ✓ |

| Gripper Lite | ✓ | ─ | ─ | ─ | ─ |

| Vacuum Gripper Lite | ✓ | ─ | ─ | ─ | ─ |

| Emergency Stop button | ✓ | ─ | ─ | ─ | ─ |

| Power Adapter | ✓ | ─ | ─ | ─ | ─ |

| Ethernet Cable | ✓ | ✓ | ✓ | ✓ | ✓ |

| Robotic arm power cable | ─ | ✓ | ✓ | ✓ | ✓ |

| Robotic arm signal cable | ─ | ✓ | ✓ | ✓ | ✓ |

| Robotic arm end effector adapter cable | ─ | ✓ | ✓ | ✓ | ✓ |

| Mounting tools | ✓ | ✓ | ✓ | ✓ | ✓ |

| Quick start guide | ─ | ✓ | ✓ | ✓ | ✓ |

| User manual | ✓ | ✓ | ✓ | ✓ | ✓ |

Why UFACTORY?

UFACTORY’s pitch is simple, multi axis collaborative robots that balance power, size, and cost, backed by open source tools.

All of their main arms share a few core ideas:

- Open APIs and SDKs. Official support for Python, C++, ROS and ROS 2, plus documented Modbus TCP and a simple TCP interface.

- UFACTORY Studio. A browser based interface for hand teaching, block style programming, trajectory recording, and system configuration.

- Safety and collaboration. Collision detection, safety boundaries, and optional six axis force and torque sensing for more sensitive tasks.

- Competitive pricing. UFACTORY cobots are often priced below many traditional industrial arms with similar specifications.

From a practical point of view, you can standardize on one ecosystem, reuse the same GUI and SDKs, and scale from a single desktop arm to a network of production cells.

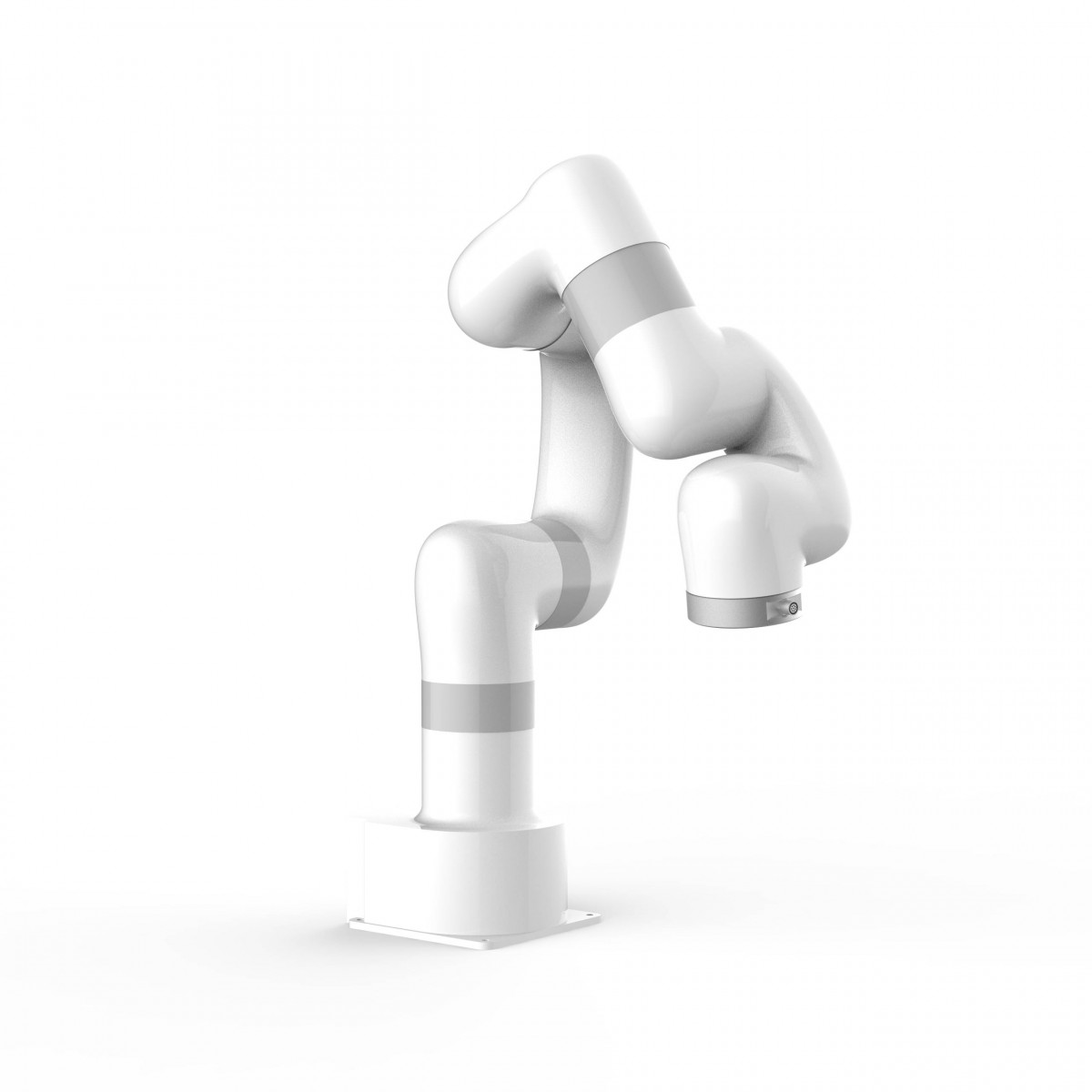

UFACTORY Lite 6

Compact Arm for Education, Labs & Light Tasks

Lite 6 is the “small but serious” UFACTORY arm. It’s a 6-DoF cobot with a 440 mm reach and about 600 g payload, built from aluminum and carbon fiber to keep the weight down while running 24/7.

Typical use cases:

- University and technical-college teaching labs

- Research benches and proof-of-concept automation

- Light pick-and-place, test automation, or vision demos

- Tight spaces where a full-size cobot won’t fit

Because Lite 6 uses the same UFACTORY Studio interface and SDKs as xArm and 850, it’s ideal as a “learning and prototyping” platform: students and engineers can develop workflows on the Lite 6 and later port them to a heavier xArm or 850 with minimal code changes.

|

|

|

|---|---|---|

| Model | Lite 6 | Lite 6 Kit |

| RobotShop Links | US / CA / EU / UK / JP | US / CA / EU / UK / JP |

| What's Included | ||

| Lite 6 Robotic Arm | ✓ | ✓ |

| Lite 6 Gripper | ─ | ✓ |

| Lite 6 Vacuum Gripper | ─ | ✓ |

UFACTORY xArm

Versatile 700 mm Cobot Workhorses

The xArm series is UFACTORY’s main cobot family, all sharing a 700 mm reach and similar industrial design, but with different DoF and payloads:

- xArm 5 – 5-axis arm, 3 kg payload, designed for simpler repetitive tasks (pick-and-place, machine tending) at lower cost.

- xArm 6 – 6-axis arm, 5 kg payload, ±0.1 mm repeatability; the “default” choice for many industrial and research projects.

- xArm 7 – 7-axis arm, 3.5 kg payload, with extra flexibility to reach around obstacles or work closer to the robot base.

All three support:

- UFACTORY Studio with drag-and-drop programming and hand-guiding

- Python, C++, ROS & ROS2 integration

- Official support for grippers, vacuum tools, BIO gripper, and third-party end-effectors.

In practice, the xArm lineup is where most of the “serious” automation case studies land:

- VR-controlled robot (Extend Robotics) – xArm plus a VR interface lets operators teleoperate a robot as easily as playing a game, lowering the barrier for non-experts.

- Bin picking & cloud vision (Aivero) – xArm robots paired with a cloud-based 3D vision system for fully automated bin picking.

- Robot competition platform (RoboHub Eindhoven) – xArm control box and SDKs are used in RoboCup@Work for a low-cost, high-performance testbed.

- Kitting, pick-and-place & packaging (CETPM, Laserlux, Taiga Robotics, VDH Systems) – xArm arms handle repetitive picking, kitting, and packaging tasks in small production environments.

|

|

|

|

|

|---|---|---|---|---|

| Model | xArm 5 AC 1.5m | xArm 5 AC 3.0m | xArm 5 AC 15m | xArm 5 DC 1.0m |

| RobotShop Links | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP |

| What's Included | ||||

| xArm AC Control Box | ✓ | ✓ | ✓ | ─ |

| xArm DC Control Box | ─ | ─ | ─ | ✓ |

| Signal & Power Cables | 1.5m | 3.0m | 15m | 1.0m |

|

|

|

|

|

|---|---|---|---|---|

| Model | xArm 6 AC 1.5m | xArm 6 AC 3.0m | xArm 6 AC 15m | xArm 6 DC 1.0m |

| RobotShop Links | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP |

| What's Included | ||||

| xArm AC Control Box | ✓ | ✓ | ✓ | ─ |

| xArm DC Control Box | ─ | ─ | ─ | ✓ |

| Signal & Power Cables | 1.5m | 3.0m | 15m | 1.0m |

|

|

|

|

|

|---|---|---|---|---|

| Model | xArm 7 AC 1.5m | xArm 7 AC 3.0m | xArm 7 AC 15m | xArm 7 DC 1.0m |

| RobotShop Links | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP |

| What's Included | ||||

| AC Control Box | ✓ | ✓ | ✓ | ─ |

| DC Control Box | ─ | ─ | ─ | ✓ |

| Signal & Power Cables | 1.5m | 3.0m | 15m | 1.0m |

|

|

|

|---|---|---|

| Model | xArm AC Control Box | xArm DC Control Box |

| RobotShop Links | US / CA / EU / UK / JP | US / CA / EU / UK / JP |

| Control Box | ||

| Input | 100-240VAC 50/60Hz | 24-72VDC |

| Output | 24VDC 20.8A | 24VDC 672W max |

| Weight | 3.9kg | 2.6kg |

| Dimension (L*W*H) | 285*135*101mm | 262*160*76mm |

| Control Box Digital I/O | 8* CI + 8* DI (Inputs) 8*CO + 8*DO (Outputs) |

─ |

| Control Box Analog I/O | ─ | 2* AI (Input) 2* AO (Output) |

| Communication Mode | Ethernet, RS485 Master | |

UFACTORY 850

Long Reach, High Precision for Demanding Jobs

The UFACTORY 850 extends the concept behind xArm 6 into a larger working envelope:

- Payload: 5 kg

- Reach: 850 mm

- Repeatability: ±0.02 mm

- Axes: 6-DoF

- Max speed: around 1 m/s linear speed

The 850 is built from aluminum and carbon fiber, keeping weight to roughly 20 kg while providing a stiffness boost. It’s available with AC and DC control boxes, making it suitable both for stationary cells and battery-powered mobile platforms.

Typical applications include:

- Vision-guided pick-and-place and bin picking

- Machine tending where the robot must reach across multiple fixtures

- Precision tasks like screw-driving, welding, or detailed inspection

- Research setups that need both long reach and tight accuracy

Because it uses the same Studio interface and xArm-Python-SDK as the other robots, you can reuse a lot of your xArm code and tooling when you grow into the 850.

|

|

|

|---|---|---|

| Model | UFACTORY 850 AC 2.0m | UFACTORY 850 DC 2.0m |

| RobotShop Links | US / CA / EU / UK / JP | US / CA / EU / UK / JP |

| What's Included | ||

| AC Control Box | ✓ | ─ |

| DC Control Box | ─ | ✓ |

| Signal & Power Cables | 2.0m | 2.0m |

|

|

|

|---|---|---|

| Model | UFACTORY 850 AC Control Box | UFACTORY 850 DC Control Box |

| RobotShop Links | US / CA / EU / UK / JP | US / CA / EU / UK / JP |

| Control Box | ||

| Input | 100-240VAC 50/60Hz | 48-72VDC |

| Output | 48VDC 1000Wmax | 48VDC 960Wmax |

| Weight | 4.8kg | 2.8kg |

| Dimension (L*W*H) | 345*135*101mm | 262*160*76mm |

| Control Box Digital I/O | 8* CI + 8* DI (Inputs) 8*CO + 8*DO (Outputs) |

─ |

| Control Box Analog I/O | ─ | 2* AI (Input) 2* AO (Output) |

| Communication Mode | Ethernet, RS485 Master | Ethernet, RS485 Master |

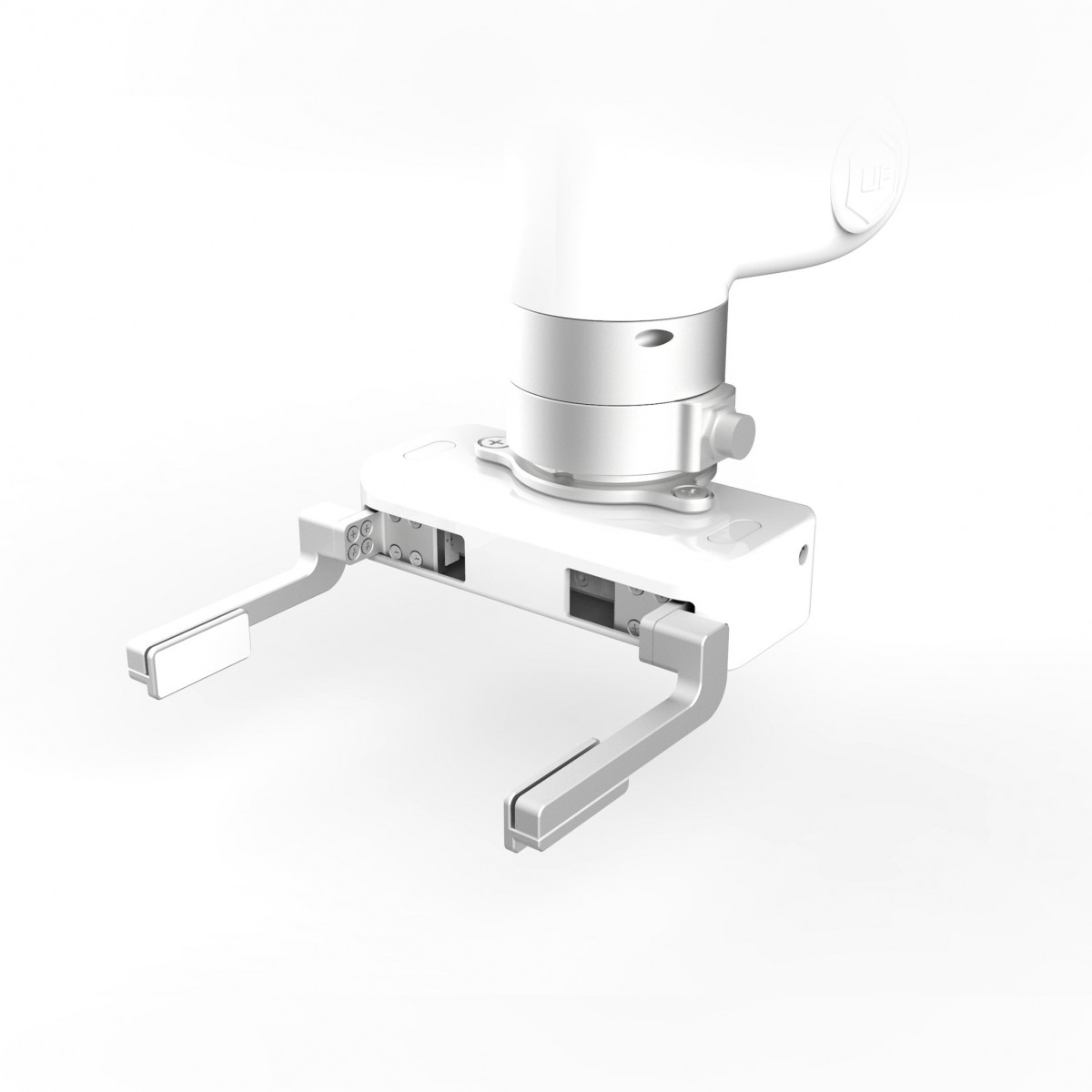

Accessories & Ecosystem

UFACTORY’s arms become much more interesting once you start pairing them with official accessories. On the Shop Accessories and documentation pages, UFACTORY highlights several categories:

End-effectors

- xArm Gripper (G2) – Parallel, 2-finger gripper for general pick-and-place.

- Vacuum Gripper – Suction-based EOAT for boxes, flat panels, and packaging.

- BIO Gripper – Soft, finger-style gripper for delicate items (food, bags, flexible objects).

- Support for third-party grippers like Robotiq 2F-85/140 via official profiles.

Sensors & vision

- 6-axis force/torque sensor for compliant insertion, polishing, or force-limited contact tasks.

- Camera stand / mounting kits for integrating 2D or 3D vision above the workspace.

Motion & control

- AC & DC control boxes for fixed and mobile deployments (including battery-powered platforms).

- Linear motor add-ons (for xArm) to extend the working envelope along a track.

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Model | xArm Torque Sensor (850) | xArm Linear Motor 700mm Kit | xArm Gripper G2 | xArm Vacuum Gripper | BIO Gripper G2 | xArm Camera Stand |

| RobotShop Links | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP | US / CA / EU / UK / JP |

| Compatibility | ||||||

| Lite 6 | ─ | ─ | ─ | ─ | ─ | ✓ |

| xArm 5 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| xArm 6 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| xArm 7 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| UFACTORY 850 | ✓ | ─ | ✓ | ✓ | ✓ | ✓ |

Case Studies by Application Area

UFACTORY’s Case Studies library is a great way to show prospects that these aren’t just lab toys, they’re running real workloads in the field.

Robotics & AI / Research & Education

- Extend Robotics (VR-controlled robot) – Combines UFACTORY arms with a VR interface to let non-experts teleoperate robots safely and intuitively.

- RoboHub Eindhoven (Robot Competition) – Uses xArm hardware and open SDKs as a platform for RoboCup@Work competitions.

- UWM BioRobotics Lab & Georgia Tech – Integrate UFACTORY arms into robotics and AI research, leveraging ROS/ROS2, open APIs, and custom tooling.

These examples are ideal to highlight for universities and R&D labs: they show that UFACTORY’s ecosystem holds up under intensive experimentation.

Industrial Automation

- Aivero (Bin Picking) – xArm robots combined with cloud-based 3D vision to automate bin picking.

- AMR Labs (Bin Picking & Teleoperation) – Mixes autonomous picking with remote operation when needed.

- CETPM (Kitting) – Demonstrates low-cost kitting solutions, with xArm robots prepping parts for assembly.

- Laserlux, Taiga Robotics, VDH Systems – Use UFACTORY arms for pick-and-place, packaging, and sorting tasks in small to mid-scale production.

These cases underline that you can start with modest budgets and still deploy real industrial workflows.

Food & Beverage Automation

- Botlegger (Coffee Vending Machine) – An xArm-driven coffee robot that automates drink preparation in a compact kiosk.

- Connected Robotics (Beer Service) – Automated beer service systems built around UFACTORY arms.

- The Flying Falafel & VLT Robotics (Automatic cooking & ice cream vending) – Show how cobots can handle repetitive, messy, or hot tasks in food prep.

These are perfect examples for readers thinking about kiosks, front-of-house automation, or ghost kitchens.

Art & Design

- RobotDoesArt (Drawing/Painting) – Uses an xArm for highly detailed neuro-impressionist artworks.

- AGI Denim (Jean Painting) – Automates denim customization and finishing.

These projects nicely show off the arms’ repeatability and fluid motion, and they’re great “hook” stories for social media or the top of the blog.

Putting It All Together: Choosing the Right UFACTORY Arm

When you’re helping a customer (or your own team) choose between Lite 6, xArm, and 850, a simple mental model works well:

Start with payload and reach

- Sub-kilogram payload, tight spaces, educational budgets → Lite 6.

- Up to 5 kg, 700 mm reach, general cobot tasks → xArm 6 for most projects; xArm 5 for simpler jobs, xArm 7 for tricky reach/obstacle clearance.

- Need more reach and precision at similar payloads → 850.

Then layer on accessories

- Simple gripper for boxes or parts → xArm Gripper G2.

- Flat surfaces or packaging → Vacuum Gripper.

- Delicate food or soft items → BIO Gripper.

- Force-sensitive work (press-fit, polishing, testing) → 6-axis force/torque sensor.

Finally, think about the development stack

- GUI-only workflows → UFACTORY Studio and hand-guiding.

- Code-heavy integration → Python/C++/ROS/ROS 2 SDKs, plus examples in UFACTORY’s docs and GitHub repos.

Conclusion

UFACTORY’s ecosystem is built around a simple idea: one family of cobots, multiple form factors, shared software.

Lite 6 gives you a compact, approachable arm for the lab bench. The xArm series covers most mainstream cobot applications. The 850 extends the same ecosystem into longer reach, high precision work. Add grippers, vacuum tools, BIO grippers, sensors, and linear motion, and you have almost everything you need to assemble complete automation cells, from teaching labs and research rigs to kitting lines, vending machines, and creative installations.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post