Future Robotics: Robot With a Human Touch

What would happen if we lost our sense of touch? Would we be able to cope? If a person were to lose their sense of touch, for example as a result of an unfortunate accident (killing all nerve endings), and no longer had the ability to feel objects around him or even the ground he was standing on, it would likely take him several months to re-learn how to walk and manipulate basic objects. Even so, the objects would need to be very solid and the manipulation may remain imprecise, relying heavily on other senses. This example illustrates the limitations of a modern robotic arm / hand without any touch sensors. A robotic arm equipped with a "real" sense of touch could perform much more complex, difficult and intricate tasks, for example, grasping an egg without breaking it. Therefore the important question would be how to give robots a sense of touch comparable to that of humans?

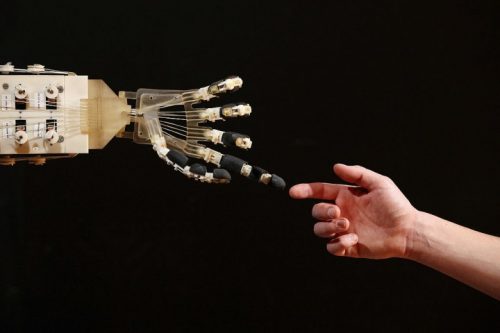

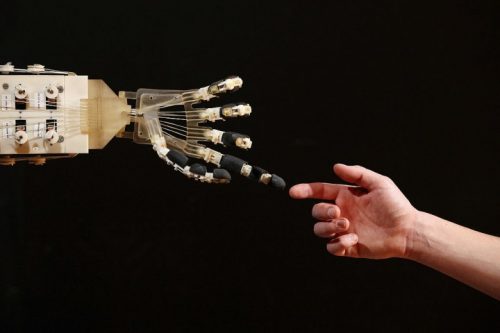

Robotic Hand with Human Touch (Photo : Oli Scarff/Getty Images)

A group of researchers at Cornell University led by Robert Shepherd, assistant professor of mechanical and aerospace engineering and principal investigator at their Organic Robotics Lab might have the answer. The Science Robotics journal recently published their paper under the name "Optoelectronically innervated soft prosthetic hand via stretchable optical waveguides", in which the researchers from Cornell University introduced their robot arm "Gentle Bot" capable of human touch.

As the doctoral candidate in mechanical engineering at Cornell and also the lead author of the study published in the journal Science Robotics, Huichan Zhao was quoted in the Cornell article; "Most robots today have sensors on the outside of the body that detect things from the surface... Our sensors are integrated within the body, so they can actually detect forces being transmitted through the thickness of the robot, a lot like we and all organisms do when we feel pain, for example."

Robotic Hand with Human Touch (Photo : Oli Scarff/Getty Images)

A group of researchers at Cornell University led by Robert Shepherd, assistant professor of mechanical and aerospace engineering and principal investigator at their Organic Robotics Lab might have the answer. The Science Robotics journal recently published their paper under the name "Optoelectronically innervated soft prosthetic hand via stretchable optical waveguides", in which the researchers from Cornell University introduced their robot arm "Gentle Bot" capable of human touch.

As the doctoral candidate in mechanical engineering at Cornell and also the lead author of the study published in the journal Science Robotics, Huichan Zhao was quoted in the Cornell article; "Most robots today have sensors on the outside of the body that detect things from the surface... Our sensors are integrated within the body, so they can actually detect forces being transmitted through the thickness of the robot, a lot like we and all organisms do when we feel pain, for example."

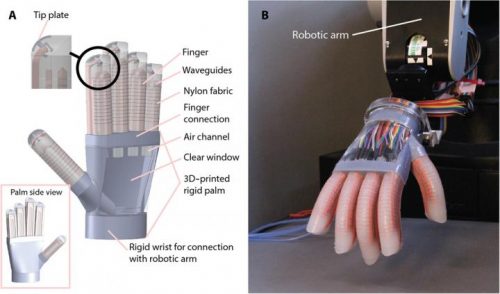

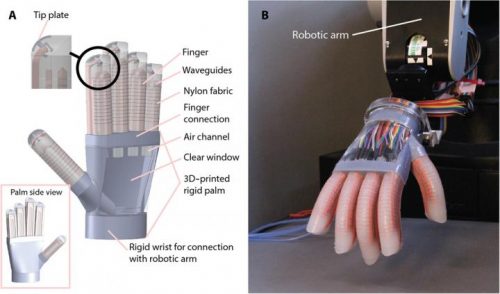

(A) Schematic of hand structure and components; (B) image of the fabricated hand mounted on a robotic arm with each finger actuated at ΔP = 100 kPa. Source: Cornell University

The industry already uses soft robotic technology to handle food products in warehouses for example. However, the Gentle Bot proves that it can beat what is already on the market handling much more delicate products. The optical waveguides have been used since the early 1970s for many detection/sensing functions. When fabrication was a fairly complicated process, the arrival of soft lithography and 3D printing led to the invention of elastomeric sensors that are incorporated into soft robotic applications. When tested, the "Gentle Bot" was able to differentiate three tomatoes and determine which one was the ripest. This robot arm can open the door to more advanced versions of prosthetics and could even directly interact with humans. The other advantage of the Gentle Bot, is that it can rely on light signals rather than electricity, therefore, it can be made with cheaper materials which will probably lead to more affordable prosthetics.

[youtube https://www.youtube.com/watch?v=5QNa9suB6FI]

(A) Schematic of hand structure and components; (B) image of the fabricated hand mounted on a robotic arm with each finger actuated at ΔP = 100 kPa. Source: Cornell University

The industry already uses soft robotic technology to handle food products in warehouses for example. However, the Gentle Bot proves that it can beat what is already on the market handling much more delicate products. The optical waveguides have been used since the early 1970s for many detection/sensing functions. When fabrication was a fairly complicated process, the arrival of soft lithography and 3D printing led to the invention of elastomeric sensors that are incorporated into soft robotic applications. When tested, the "Gentle Bot" was able to differentiate three tomatoes and determine which one was the ripest. This robot arm can open the door to more advanced versions of prosthetics and could even directly interact with humans. The other advantage of the Gentle Bot, is that it can rely on light signals rather than electricity, therefore, it can be made with cheaper materials which will probably lead to more affordable prosthetics.

[youtube https://www.youtube.com/watch?v=5QNa9suB6FI]

Robotic Hand with Human Touch (Photo : Oli Scarff/Getty Images)

Robotic Hand with Human Touch (Photo : Oli Scarff/Getty Images) (A) Schematic of hand structure and components; (B) image of the fabricated hand mounted on a robotic arm with each finger actuated at ΔP = 100 kPa. Source: Cornell University

(A) Schematic of hand structure and components; (B) image of the fabricated hand mounted on a robotic arm with each finger actuated at ΔP = 100 kPa. Source: Cornell UniversityThanks for helping to keep our community civil!

Notify staff privately

You flagged this as spam. Undo flag.Flag Post

It's Spam

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post