Buyer's Guide: How to Choose / Compare 3D Printers

A 3D printer is a device used to create three-dimensional objects like toys, tools, model airplane parts and more from a digital 3D file. Around 10 years ago, 3D printing was relatively unknown and unused beyond the professional community. The machines were very expensive and sophisticated, specially designed for industrial use and not really affordable for the general public and were used mostly by designers and engineers to make complex pre-production prototypes, or one-off devices. Nowadays, 3D printers are becoming more accessible to the general public, with competitive prices, low maintenance and a multitude of features. With it, the market is experiencing a huge influx of 3D printers, with new models being released almost every week. In the near future, having a 3D printer at home will be as common as having a television or a desktop computer. However, the question remains : how do you choose a 3D printer that fits your needs?

*More ABS and PLA filament colors are available here.

Unlike the filament that has become almost standardized in two sizes (1.75mm and 3mm), the spools still come in a lot of different sizes. The spool size and dimensions is an important characteristic to consider, since it's different from a printer to another. First thing to notice, is that some 3D printers have a closed holder for the filament spool while others contains an opened one. Usually, the printers with a closed spool holder will take coils made by the same manufacturer or sometimes, made especially for that 3D printer. To choose an appropriate coil of filament for your 3D printer, you might need to know the outer size diameter, the inner spool diameter, the mount hole diameter and the weight.

• Printing Speed : A typical desktop FDM 3D printer prints at ~40mm/s to 150mm/s. It means that the printer is able to extrude 40-150 mm/sec molten filament every second. This attribute is directly dependent on the the printing resolution. The higher the resolution, the slower the speed and vice-versa. The type of material used and the complexity level of the print can also affect the printing speed. Despite having a same volume, a model with a lot of corners and edges will be slower printed than a sphere for example.

• Layer Resolution : Similarly to photography, the resolution of the final printed object can be chosen and you can choose to create high and low resolution objects. A high resolution object tends to be relatively smooth, has very thin layers and sometimes (with very high resolution) it's difficult to see each individual layer whereas a low resolution object has thicker layers and it's easy to see each layer. Some 3D printers allow you to enter a value of the layer resolution (each printer has min and max values) whereas others provide two or more resolution options such as "low", "medium" and "high":

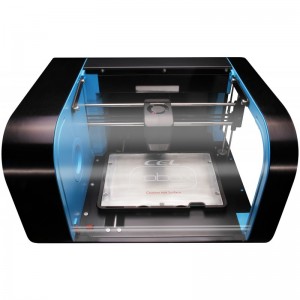

• Extruders : In FDM printers, the extruder assembly involves a heated printing nozzle (the part responsible for melting and extruding the printing materials) as well as a motor which forces the filament into the nozzle, a temperature sensor and often times a cooling system for the motor itself. One aspect which is important to consider is how many extruders a 3D printer includes. More than one extruder will allow you to print an object in different colors and/or different materials. Most 3D printers on the market have one nozzle per extruder with the exception of the CEL Robox 3D printer which has two nozzles with one extruder and this dual-nozzle system can improve print speeds by up to 300%.

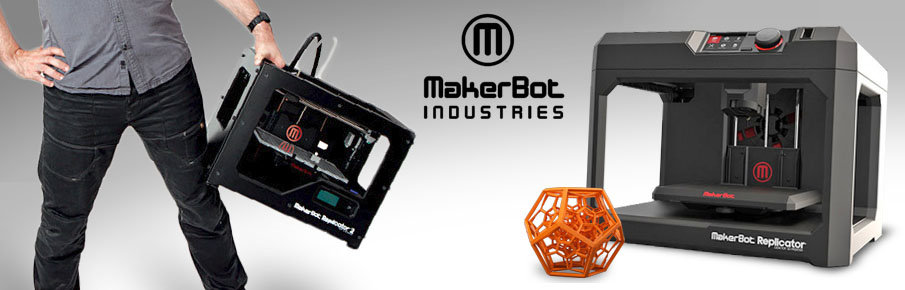

3D Printing Technology

The first thing to know about 3D printers is the printing technology, since not all printers use the same. Most home 3D printers use a process called "Fused Deposition Modeling" (FDM) also sometimes called "Fused Filament Fabrication" (FFF) or "Plastic Jet Printing" (PJP). This printing technology is the process of making a three-dimensional object by laying down successive layers of a specific material (normally plastic) layer by layer until the entire object is made. The layers are like horizontal cross-sections of the object which were created by the 3D modeling software and formed by extruding a continuous length of plastic material using a heated nozzle which hardens almost immediately after extrusion. Some other home 3D printers use a process called "Stereolithography" (SLA) in which a laser solidifies layer on layer of photosensitive resin to form the part. Here are some 3D printers which use FDM printing technology:Printing Material, Filament and Spools

The next thing to consider is the compatible printing material itself. Most 3D printers use a spool (or Coil) of filament in either ABS (acrylonitrile butadiene styrene) or PLA (polylactic acid) available in all kinds of colors. Many printers in the past used both ABS and PLA, and many still do (like the Cube or CEL Robox). These two plastic materials are known as thermoplastics, which means they can be heated to become flexible (semi-liquid) and as soon as they are cooled they revert back to being solid, no matter how much the process is repeated. ABS material is flexible, strong and has a high temperature resistance which is why it's preferred for professionals. PLA can arguably produce thinner layer thicknesses, sharper printed corners and is available in a wide range of colors which makes it preferred by schools and hobbyists. A major difference however between ABS and PLA is that PLA is corn-based and as such is significantly more biodegradable. Nevertheless, you do not need to worry about your parts "going bad" any time soon as PLA still lasts a long time. There are quite a few other options available: • Nylon : There are a several types of Nylon material used in 3D printing, the most popular is the Nylon 618. It has a natural white color that can be colored according to your tastes. It has great bio-compatibility and is mostly used in the medical industry. • Resin : This material creates particularly smooth and precise objects with its rich texture. However, exposing a Resin printed object to UV light will cause its discoloration. The users of this type of material usually paint the model with varnish after printing. • Wood : This filament is a mix of recycled wood and binding polymer. If you like to create objects that look and smell like wood this printing material is for you. The printing process with Wood is very similar to the one with ABS and PLA. • HIPS : High Impact Polystyrene filament is a good example of support 3D materials. It has an interesting property that makes it well suited as a support material. However, its filaments have adhesion problems, which can be reduced by using a heated bed during the printing. • Stainless Steel : This material is a mixture of hybrid of stainless steel and bronze. It's the hardest of all 3D printing materials. Usually, desktop 3D printers cannot print in this material. ABS and PLA are available in spools* with two common filament diameter sizes: 1.75mm or 3mm, and not all 3D printers are compatible with both diameters compatibility. It should be noted that some 3D printers have a special ABS or PLA cartridge and as such, it is strongly suggested that you purchase replacement filament produced by the same manufacturer as the 3D printer. One example is the Cube 3D printers which uses cartridges such as the last one below:3D Printing Attributes

We suggest choosing a 3D printer that is suited for your requirements based on several key performance attributes. Here are some 3D printing performance aspects to consider when comparing 3D printers : • Build Volume/Print Area : Obviously the bigger the build area, the bigger the objects which can be create within the printer. The largest build volume for commercial 3D printers at the time of this article is available with Stereolithography (SLA) allowing designers and engineers to print up to 1m³ objects ("one-off" printers have created even larger parts). For most desktop / hobby 3D printers, build volume will not exceed 380mm³. Usually, 3D printer manufacturers provide the build volume or dimensions (width x depth x Height) in inches or millimeters :

MakerBot Replicator Z18 Printer MakerBot Replicator Z18 PrinterBuild Volume : 305x300x457mm |

Features

Other than printing 3D objects, 3D printers offer many interesting features that can make the printing experience quite easy and enjoyable. Some of these features are listed below : • Connectivity : Most 3D printers rely on a USB connection (mostly type B) and computer to print an object using a slicing software. Certain printers have the ability to print via Ethernet or wirelessly using a WiFi connection (from a PC or even a mobile phone). It's interesting to know that a few 3D printers include a USB or SD card slot so as to not have to rely on an external computer during the build process. • LCD and Display : It's always a pleasure to have a visual display on gadgets and with 3D printers, this is no exception. It can be a character or graphical LCD display, touchscreen or even some colored LEDs that relay useful printing information such as printing progress for example. • Assembled vs Kit : Today it's easier than ever to build gadgets and invent devices at home. Some 3D printer manufacturers give the user the opportunity to assemble their own 3D printer without much difficulty. Not all 3D printers come assembled, some of them come in a DIY Kits like the Makeblock Constructor 3D Printer. This approach often results in price savings since the manufacturer does not need to assemble, calibrate and test the machine. • Additional features : 3D printers come in different forms and designs but also a range of functionalities and extra accessories. Before buying a 3D printer, it would be wise to consider some of these additional features. Here are some examples that your future 3D printer might include : - All-in-One 3D Printer : A 3D Printer that combines copying, printing, scanning and faxing in one machine. Like the Zeus All in One 3D Printer : - Camera : An on board camera can be useful for monitoring printings. Mostly, the camera is accessible through a PC or a mobile phone so that we can always have an eye on our in-progress printing objects and easily take pictures of the final print : - Automatic Material Recognition : Some 3D printers automatically recognize the printing material installed. Depending on the type of filament, the printer display will show PLA, ABS or other material. Like the CEL Robox® Dual-Head 3D Printer : - Aesthetics : Although not a technical feature, a printer's appearance can play an important role and influences our choice. For this reason, new 3D printers have attractive frames, and machines no longer look like something which was put together in a garage but instead a professional and aesthetic addition to the workshop. :3D Printing Software

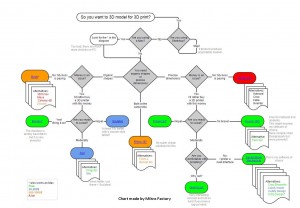

Most, 3D Printers provide their own 3D printing software (or Slicing software) that can open and print STL files. An STL file is the standard file format that you might use to print your 3D model into a physical object. It contains the information (series of triangles and their XYZ coordinates) needed to produce a physical object layer by layer. Like a traditional 2D printer, with a 3D printing software you can rotate, scale and resize the model. You can also choose different 3D print settings like layer thickness and fill type. However, to design and create your own objects, you may need a 3D modeling software. There are a wide variety of 3D modeling softwares both free and commercial that will help you bring your creation alive (123D Design, Sketchup, Autodesk Inventors Fusion...). The STL file can be generated using most 3D modeling programs. Here is a decision chart to help you choose the 3D modeling software that fits your needs :Price

Last but not least, choosing a 3D Printer is like choosing any other household device. It will depend on the budget you're ready to invest. Concerning desktop 3D printers, the price range goes from 200$ to 4000$. Needless to say, higher the price, higher the quality of prints and more features you'll have. Usually, the price of the printer will directly reflect its output quality and functionalities. However with the popularity increase of 3D printers and the rough competition between manufacturers, the prices of printers will go down while the quality will improve.Conclusion

Finally, choosing a 3D printer could be quite a challenge. However, when you ask yourself the question : What will it be used for? You are already aiming for the right one. Hopefully, this article was helpful enough to guide your choice providing the most important attributes that all 3D printer have in common. Before taking a decision, try to step back and visualize all the important specifications you need for your application and compare them with the existing 3D printers. Then, you'll be buying the right one. Here is our 3D Printers Comparison Table that will help you choose the 3D printer you need. If you still have questions about choosing a 3D Printer, please feel free to contact us via our Forum.Thanks for helping to keep our community civil!

Notify staff privately

You flagged this as spam. Undo flag.Flag Post

It's Spam

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post