Beeptoolkit for the safety of passengers.

Automobile companies have been conducting crash tests since the 1930s, and in the middle of the last century, such tests began to be arranged by independent institutes of road safety. During this time, much has changed in the methods of conducting crash tests: in addition to frontal and side collisions, tests have appeared that simulate a car rollover, a collision from behind or a collision with various objects, a collision with large animals.

An elk camel or elk crash test has nothing to do with testing a car during extreme maneuvers. On the contrary, engineers deliberately arrange a head-on collision with a model of this animal weighing about 450 kg at a speed of 70 km / h. Similar crash tests were regularly carried out in Sweden - this is where the largest number of accidents with animals are recorded.

Over the past ten years, crash tests have become commonplace in the passive safety of children. A huge number of independent organizations in Europe, America, Japan are conducting similar tests of child car seats, not to mention testing during the development and certification of these products.

It is logical that the next new safety accessory will require a crash test, which in the future will need to be quickly reconfigured for other new systems in the context of in-line production and fierce competition from other manufacturers.

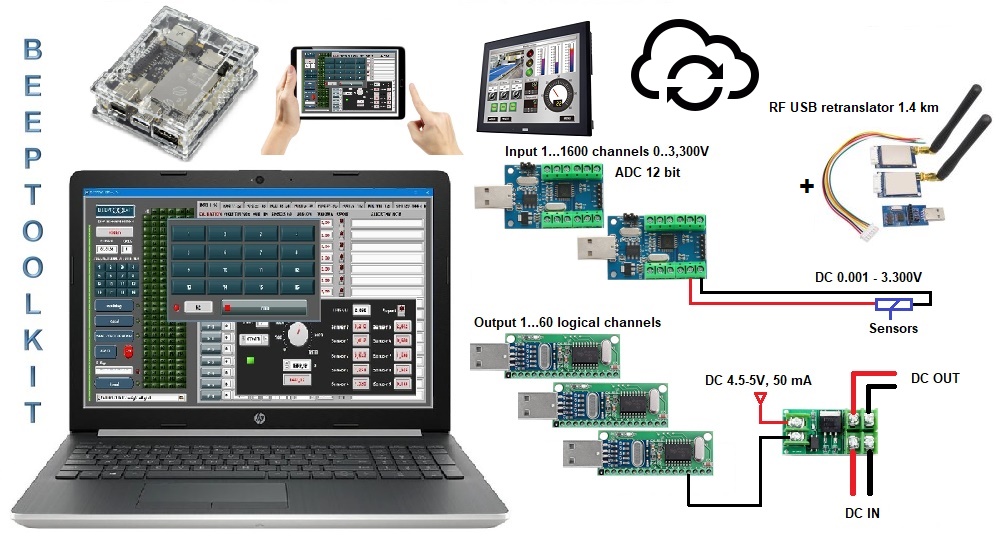

Let's take a look at how the BEEPTOOLKIT elegantly solves such problems.

One-touch concept design and prototype firmware.

Algorithm:

The dynamic stand is shown in this image.

The system allows you to adjust a specific collision speed (fall, rollover, extreme braking, etc.)

The stand is driven by a high-speed electric stepper or servo motor.

The speed and distance to the obstacle is measured with a LIDAR.

The force of impact on certain points of the bodies of passengers is recorded at the moment of collision by strain gauges, the number of which can reach several hundred.

The program in real time generates a report on the impact force on the points of the bodies of the models.

For completeness of verification, the original report file can be transferred to the analytical database, where the results of crash tests are presented in accordance with the regulatory documentation for transmission to the regulatory authorities.

Follow our updates and publications.

We would be grateful for your feedback, questions and criticism.

Next time we will tell you about the automation of testing electronic (ATE) SMD modules.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post