7 Innovative Trends in Robot-Assisted Pharmaceutical Manufacturing

Even though pharmaceutical manufacturers have historically preferred to stick to well-established technology, times are changing. Now, robot-assisted production has become popular, and the industry-wide trends are apparent.

Robot-Assisted Technology Is Growing Popular

In the pharmaceutical sector, robot-assisted technology is rapidly growing in popularity. In recent years, manufacturing facilities’ interest has suddenly increased. Enough time has passed for industry trends to become apparent.

Globally, manufacturers installed hundreds of thousands of industrial robots in 2021. As a result, the robotics market’s growth rate reached 31% between 2020 and 2021 — a new record. Previously, the highest it had ever been was 22% in 2018.

Even though the pharmaceutical industry usually adapts to new technology slowly, its adoption rate has increased recently. An industry-wide skill shortage and high demand caused by the pandemic have motivated it. Now, manufacturers want to streamline their processes with the latest robotic innovations.

The Benefits of Robot-Assisted Manufacturing

Robot-assisted pharmaceutical manufacturing is growing massively because it provides a wealth of benefits. Manufacturing facilities are accelerating their adoption of these technologies because it makes them more competitive and protects end-users well-being.

By nature, humans make mistakes. In fact, they cause 80% of process errors in pharmaceutical manufacturing. Every slip-up costs time and money, so manufacturers are turning to robots. These machines can work without breaks and rarely miscalculate, which lowers production costs.

Another reason why more manufacturers are adopting robots is the industry-wide skill shortage. Instead of slowing production until it improves, they use robots to fill the gap. Because labor makes up 30% of manufacturing expenses, they even save money.

The entire pharmaceutical industry will benefit from robot-assisted manufacturing. Since these machines save time and lower production costs, people may see medication prices shrink. They can also increase medication quality, improving end user safety.

The Top Trends in Pharmaceutical Manufacturing

Robotics is becoming popular in many different aspects of pharmaceutical manufacturing. Labor shortages and the COVID-19 pandemic have significantly increased demand throughout the sector. However, the adoption rate is accelerating particularly fast in a few key areas.

1. Quality Control

Robot-assisted quality control is becoming much more common in pharmaceutical manufacturing. Since medications must be contaminant-free, the production process must be sterile. Robots are one of the few technological solutions capable of meeting these strict standards.

Currently, handling has a high margin of error. In fact, the United States Food and Drug Administration has recalled 3,770 types of drugs since 2012. It has removed tens of thousands of medications from the market because of inaccuracies.

Manufacturers can use robots in all kinds of quality control processes, from batch testing to cleanroom decontamination. For example, an ultrapure water treatment system purifies water for safe equipment sterilization or ingredient mixing. Micro versions are 40% smaller than conventional systems but have a 60% higher output.

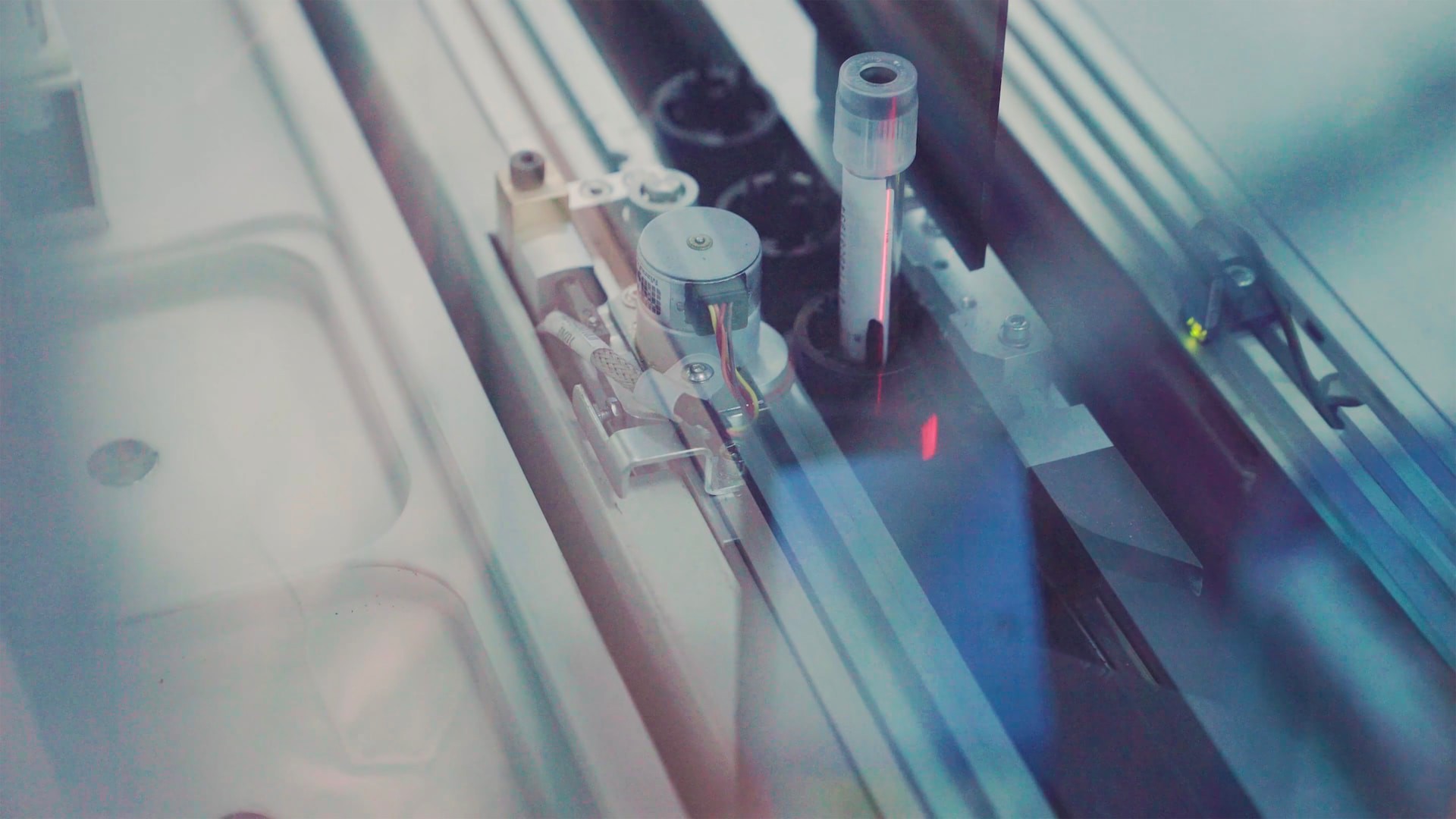

2. Sensing and Vision

Sensing and vision robots are among the most innovative advancements in pharmaceutical manufacturing. These machines can use state-of-the-art technology like haptic feedback to orient themselves. This way, fewer machine errors occur, and their output increases.

Additionally, these robots use cameras and artificial intelligence to achieve machine vision. Essentially, they can see and react to their environment in real time. For example, stationary machines can scan medication barcodes. Alternatively, cobots can watch where their human partner moves to avoid injury.

While cobots quickly grow in popularity, sensing and vision technology has yet to become as widespread. Although it is revolutionary for safety and quality control, tools like AI-powered cameras are recent innovations. Still, these robots will likely take over the industry in the coming years.

3. Artificial Intelligence

The pharmaceutical industry already uses algorithms in drug development and testing. In other words, the manufacturing sector’s adoption has been a likely possibility for ages. AI-powered robot-assisted production is cutting-edge. With this technology, manufacturers can improve cobot safety, drug defect detection and object picking.

4. Collaborative Robots

Collaborative robots — otherwise known as cobots — are one of the largest trends in pharmaceutical manufacturing. Experts believe their global market value will reach $1.99 billion by 2030, a roughly $1.4 billion increase from 2020. If humans and machines work together, they can compensate for each other’s performance gaps.

Even though cobots are relatively new, versions that can fill containers, move medication or dispense ingredients already exist. In fact, the world’s smallest cobot weighs only 6 pounds and can lift one-third of its weight — the ideal size for small-scale work. Pharmaceutical manufacturers can use innovative technology like this to improve their assembly lines.

5. Pick and Place

The widespread skill shortage and the after-effects of the COVID-19 pandemic have motivated manufacturers to increase distribution rates. Since manually moving boxes is time-consuming, the industry is seeing a significant uptick in pick-and-place robotics.

Pick-and-place robots are sensitive enough to move delicate test tubes and strong enough to lift boxes full of medication. As more manufacturers realize how versatile they are, their adoption rate will increase. They will likely become industry-standard within a few years.

6. Modular and Flexible

As pharmaceutical demand skyrockets, manufacturers want a solution that can adapt to change. With modular and flexible robots, they can combine, reconfigure and readjust as their needs shift. Instead of installing dozens of machines, they can keep and modify a handful. This technology will undoubtedly grow even more popular once it’s established.

7. Mixing and Dosing

More manufacturers are starting to use robots for mixing and dosing, as production requires extreme accuracy. In one study, a robot only had a 5% error rate when handling medication — it was more accurate than the human workers were. Even though mechanical faults happen occasionally, they’re relatively rare.

Notably, the robot in the study also spent less time preparing. It even used fewer materials to produce more medication than humans did. As more manufacturers notice the benefits of robot-assisted mixing and dosing, more will adopt the technology.

The Future of Robot-Assisted Pharmaceutical Manufacturing

These trends are likely the most impactful the pharmaceutical manufacturing industry will experience for years. The various production, safety and cost improvements will undoubtedly have a substantial long-term impact. Best of all, more robotics innovations are bound to appear as manufacturers explore their new technology.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post