4 Reasons Why Robots Help Businesses Meet Increased Demand

Some people may be surprised to learn how rapidly the robotics industry is growing. By 2027, the market is expected to top $100 billion. Countries all over the world are adopting new technologies that will hopefully create economic growth.

The COVID-19 pandemic thrust the country into the future of automation. Industries across all sectors are scrambling to find innovative ways to meet demand, and many are turning to robotics. Robots offer benefits that humans do not, so their implementation is necessary for some businesses. Automating the cleaning process is just one example of how businesses can start to implement them.

The Robot Revolution

It’s challenging to predict just how prevalent robots will be in upcoming years. Current trends lead many people to believe they will take over the workforce in many sectors. Robots have been around for much longer than one might think — it was over 2,700 years ago that the first humans thought about artificial people or robots. In 2021, we’re closer than ever to seeing these early thoughts come to fruition.

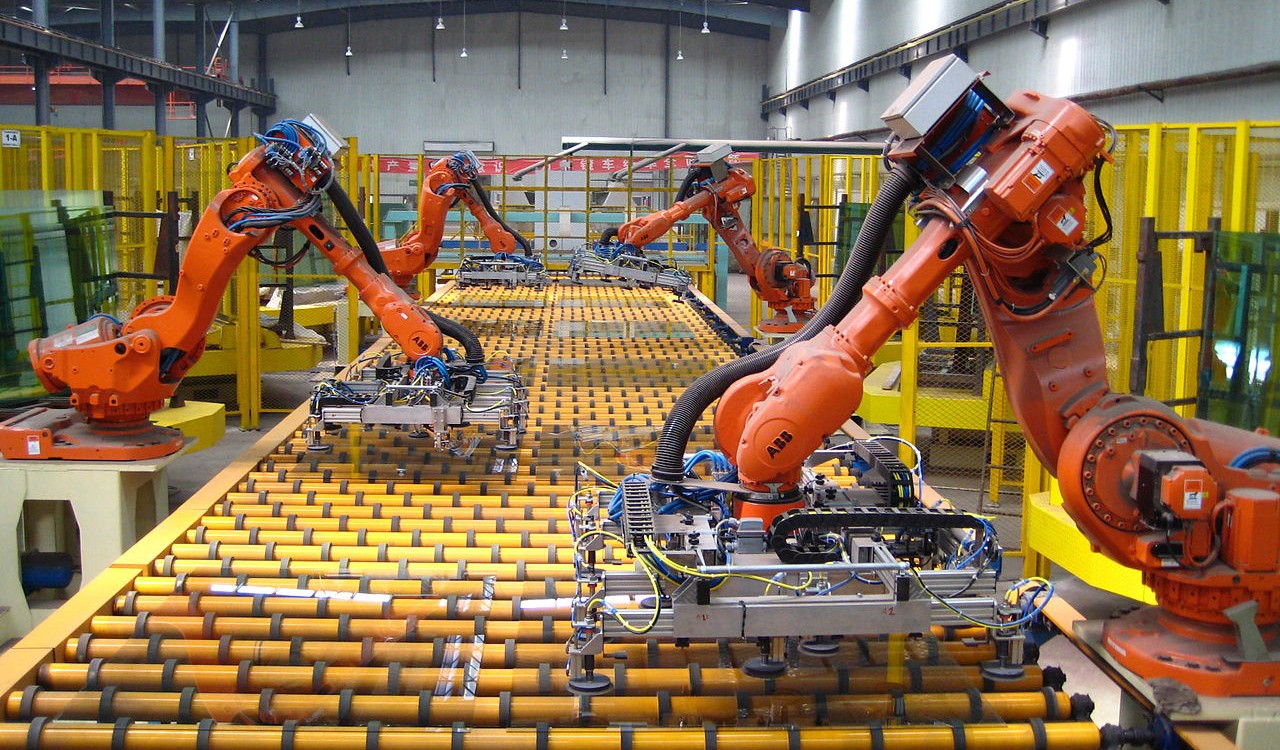

There’s an apparent demand for automation — for example, the automotive industry benefits from robots in daily operations. Whether it’s robotic welding or painting cars, many tasks are made easier with robotics.

Discussing the increased demands many industries face after the pandemic is crucial. It’s no secret that keeping up with demand requires a willingness to utilize top-tier technology to improve business processes. As a result, robots will remain at the center of most conversations regarding possible solutions to common industrial problems.

Industry Demands Post-COVID-19

As the U.S. emerges from the pandemic, there will likely be an increased demand for consumer goods and services. The effects of COVID-19 on consumer behavior are still unclear but need to be addressed. How are people shopping? What items are in the highest demand now? For the industries serving the average American consumer, it’s normal to have these types of questions.

Businesses are reopening, unemployment rates are declining, and there’s an overall sense of optimism coming from entrepreneurs and industry leaders. The country may experience a strong growth period post-pandemic. The result will be an increased need for manufactured products, and industries will need to be creative in how they meet that demand.

Companies in the information technology (IT) sector are focusing their efforts on artificial intelligence (AI) and machine learning (ML). Therefore, it’s essential to think about how to apply these advanced technologies to various industries.

One goal of using robots is to have them work alongside employees to simplify the tasks they complete daily. The level of collaboration between man and machine will determine how applicable robotics are in a specific industry.

4 Reasons Robots Help Businesses

Strong supply chains and strategic logistics management are the building blocks of any industry. Producing goods or offering services to other businesses or consumers is what allows the economy to grow and flourish. How do robots help these companies with their production? What benefits do robots have to offer?

Here are some reasons why robots can help businesses now and in the future:

1. Increased Efficiency

Having machines do the heavy lifting can dramatically improve efficiency in warehouses and manufacturing plants. Robots are programmed to complete repetitive tasks, and they often spend less time on jobs than a human worker. Whether it’s a self-driving machine that can move pallets or a robot that can pack items to ship, processes become more efficient.

2. Improved Workplace Safety

There are many safety hazards during a typical workday, especially in construction and ironwork. Unfortunately, while there are standards and procedures to follow, there’s no way to guarantee workers are protected from workplace accidents. Thankfully, robots can complete dangerous tasks without the fear of a human being injured.

3. Higher Productivity

Because of their advanced systems, robots can work for hours without any breaks for extended periods. This increased productivity can help companies better serve their customers.

4. Quality Supply Chains

Regardless of the industry, a supply chain needs to run like a well-oiled machine for businesses to succeed. One issue the pandemic caused was worker shortages within the supply chain. If one part of the chain fails to meet a quota, everything is impacted negatively. Using robots to prevent these initial failures will reduce disruptions, and supply chains will run more seamlessly.

As the robotics market continues to grow, more analyses of the positive effects will guide researchers and developers in their work. When common issues in manufacturing are identified, the right people can begin working toward finding appropriate solutions. Meeting demand by reaping the benefits listed above will improve business performance and lead to economic growth.

Industries Benefiting From Using Robots

Even before the pandemic, several industries used their resources to invest in and implement robotics.

Countries like Japan and China are also at the forefront of robotics technology and have specific goals they’d like to reach in the next few years. Thus, finding practical ways to apply new technologies to industries is a top priority for many countries.

Here are some of those industries that already benefit from using robots:

Health Care

Surgical robots and telemedicine are now commonplace in hospitals and medical care centers. Although humans are still needed to carry out most tasks during surgeries, robots assist doctors in hysterectomies and lung surgeries.

Military

A practical application of robots in the military is the use of unmanned drones and other equipment. For instance, if a team performs an extraction mission, drones help soldiers analyze any dangers before entering an area where they could be vulnerable.

Agriculture

Using AI in the agriculture industry allows farmers to spend less time on mundane tasks. For example, robots on farms can seed, harvest, control weeds and add chemicals where they’re needed. As a result, the robotization of equipment in farming yields higher productivity levels and reduces costs simultaneously.

Manufacturing

One of the more prominent beneficiaries of robotics in industry is manufacturing. So many of the tasks performed by humans are repetitive, and it’s becoming easier to program robots to complete those jobs. Amazon is a leader in the robotics industry, with more than 200,000 robots working in its warehouses globally.

Meeting Demands of Customers and Robots

These are only a few of the industries that are seeing noticeable improvements in their processes by using robotics. The ability to meet customer demands is a determining factor of success. If sectors fail to do so, there’s no room for growth.

It’s also important to note that maintaining robotics is no easy task. Robots have many moving parts that allow them to accomplish tasks, but what if they go bad? Who will be there to fix them? There may be a demand for specialized technicians to take care of these potential problems.

The Future of Robots in Industry

It’s common knowledge that supply and demand are constantly fluctuating. As a result, industries are faced with the challenge of forecasting demand to keep up with the needs of their customer base. With AI, ML and new robotics technology developing, industries like health care and manufacturing will be the first to apply them to their business processes.

Whether it’s performing a minimally invasive surgery or analyzing data on the battlefield, robots will offer an array of benefits. Industry leaders must be willing to adopt new technologies to stay ahead of their competitors.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post