@Coleman Benson am I right that computed torque here is the STALL TORQUE?

Do you what is larger between STALL TORQUE and RATED TORQUE? If I consider the Rated Torque what values I need to add up?

@Eugene Agustin The torque provided is simply the torque needed to maintain that position, without any acceleration. “Stall” generally indicates the motor is impeded from rotating and will still try its best, causing it to heat up very rapidly and burn. Rated torque generally means the torque which the motor can provide without issue. If you wanted a margin of error, you should consider the torques calculated here to be the torque at maximum efficiency" for the motor. Torque at max power would only likely last a few seconds.

@Coleman Benson So what is greater between stall torque and rated torque? How large is the greater between the two? BTW thank you for the explanation.

@Eugene Agustin Stall torque is the absolute max a motor can provide - to the point where the shaft cannot rotate and the motor would burn. The rated torque is what the motor can provide safely. Therefore the value for stall torque is quite a bit higher than the value for rated torque.

@Coleman Benson Thank you for your explanation. If the result of the calculated torque here is 500kg-cm. What value of rated torque of the motor should I look? Is it less than 100 or half of the result or what? (just an assumption will help). Thank you.

@Eugene Agustin Wow. For the arm to remain in place at full reach with full load, that’s the torque your shoulder motor will need. As soon as you drop the load at full reach, it should be able to move. You should consider using linear actuators. Note that in the 500Kg-cm range, you’ll need to consider industrial actuators. Remember, every gram at full reach has a huge impact on the shoulder motor.

Hello Sir, i plan to make 3DOF articulated robotic arm. I just want to know if MG996R base servo (9.4kg/cm stall torque) is enough to rotate the robotic arm (including shoulder, wrist, till end effector, and targeted object) that has weight ±211 gram. and has maximum length of 24 cm if its extended from the center of rotation to the end effector. Please reply asap, Thank You

Welcome to the community Khoukou. Lynxmotion’s RC-based AL5D arms use the Hitec 485HB in the base, which is spec’d at 5.2kg-cm to 6.4Kg-cm, so yours should work provided their specs are accurate. The general idea is that horizontally, there’s not a lot of static or dynamic resistance to motion.

Hey @cbenson,

I hope you are doing well. Thanks for this awesome tutorial. I calculated the torque required at each joint with this tutorial, I wanted to know if the same torque is applied to the link? if yes, in what direction. as I want to calculate the total deformation of the link in Ansys.

Thanks once again

@JJenn Welcome to the RobotShop Community. The links between joints can be treated as beams subject to force as opposed to torque. You will need to sum the weight acting at the end of each beam (and to be accurate, the weight of the beam itself at its center of mass) to calculate the deformation.

Uh-oh hello, there is few thing that i dont quite understand when i calculate the joint by myself i use gravity in the formula and pretty much get a triple digit of torque when in this calculator i only get 2 digit how does this calculator work exactly? just like in the tutorial? which mean not counting for gravity?

@RIzami Welcome to the RobotShop Community. If you’re using a force as opposed to a mass, you’re factoring in gravity, For example Kg is a mass, while Newtons ( 1N = 9.81 x 1Kg) is a force. It will depend on what value you want for the torque (ex. Kg-cm vs. Nm).

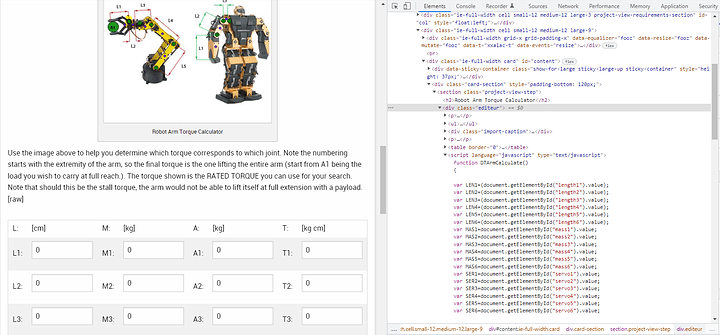

oh good lord i just realise i am using cm in the force calculation and about to get a 100kg torque thank god i was wrong. Also the calculation that i am doing here should be the stall torque no? which mean my servo can hold it but cannot move itself.

It’s really up to you to interpret the torque and select accordingly. Normally dynamic torque is 1/4 static, so the arm will be able to hold itself straight outward, but won’t have enough torque to move up (it can move down though). If you want it to move up from fully extended and maximum load, you’ll need to multiply the value you get by around 4 (napkin math).

Hello sir,

As u have said that it does not calculate Torque for acceleration but only for against gravity and with a safety factor of 2 . So do i need to multiply the value (eg Motor 1Torque) by 2 to get approximate value for total Torque or its already multiplied by 2 and that’s the final Torque.

@Vaibhav8181 Welcome to the RobotShop Community. I don’t think the output values have been altered at all in the calculations, so they are just providing the “steady state” torque (i.e. static / not moving). When you look for a motor, the manufacturer often provides the “stall” torque which is never intended to be reached (preventing the motor from rotating burns it), and only more expensive motors tend to include the torque at max efficiency and max power. The “torque at max power” value provided by the motor manufacturer would be what would correspond to the output of the “Torque Calculator” without a multiplication value of 2. However since many motor descriptions / specs (especially for RC servo motors) don’t have that, the comfortable “dynamic” torque (i.e. under motion) provided by many DC motors is only around 25% of their “static” torque, though in many cases it can be pushed up to 50% for very brief periods, which is why the “napkin math” is to multiply the static torque value by at least 2.

If you’re curious about the equations used in the code, you can press F12 in most browsers, select the section with the input values and expand until you get to this section labeled “editeur”:

Thankyou sir. Btw I going to use stepper motors.

Stepper motors are quite different than brushed / brushless DC motors - their control method is very different and they offer higher torque at lower speeds. Note too that the step mode (full step , half step etc.) also affects the torque, as does the input voltage. Absolutely read a lot about stepper motor operation.

hey, I used your calculator and got a required torque of 612kg-cm at the base, so according to that if you have any knowledge in this field can you suggest one good stepper motor for this torque.

I know using gears will increase the torque output of the motor but I could only find a 20kg-cm stepper motor, so if you could share any details of a motor it would help me a lot. thanks

@robosahith Welcome to the RobotShop Community. If you can only find a 20Kg-cm stepper, you’d need at least a 30:1 (if not more) gearbox to get the ~600Kg-cm needed. Is 20Kg-cm the MAX torque which the stepper can provide? If so, that’s enough to maintain the arm at full reach, but not enough to lift it.